The ceramic grinding wheel impresses with its ultimate aggressiveness and very good tool life. Due to the self-sharpening result of the high-performance ceramic oxide grain in assembly with a special bond technology, the tool preserves its abrasiveness throughout its whole tool life. This results in fast work progress and significant savings in labor costs associated with the use of predictable reinforced grinding wheels. Also, it allows work to be performed with very less effort.

Materials that can be worked with ceramic grinding wheel

- Steel and

- stainless steel

Applications of ceramic grinding wheel

- It can be used in Surface grinding

- It works on weld seams

- It is used in chamfering and deburring

- The Optimum grinding results in a high-powered angle grind

The Metal bond grinding wheels are formed when powdered metals containing cubic boron nitride are sintered on the wheel, ensuing in exceptionally robust tools that maintain shape during severe use. The metal bonding of ceramic grinding wheels extends the life of the grinding wheels by dropping the need for recurrent dressings and continues being productively extended than branded super abrasives. The Metal Bond wheels are destined for high resistance to wear claims and tend to give mainly long life. The high mechanical stability and the thermal load capacity of Metal Bonds give them a great resistance to wear. This is used especially in connection with the grinding tools for profile grinding of materials that exhibit an abrading effect, such as glass, ferrite, etc.

Choosing The Right ceramic grinding wheel

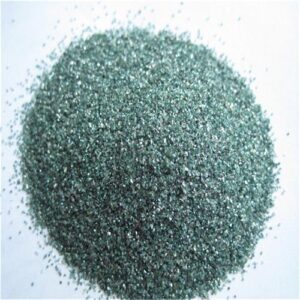

In a grinding wheel, the abrasive achieves the same function as the teeth in a saw. The ceramic grinding wheel has abrasive grains dispersed through the wheel. Abrasive suppliers bid on an extensive array of products for an extensive array of grinding applications. Choosing the incorrect product can cost both time and money.