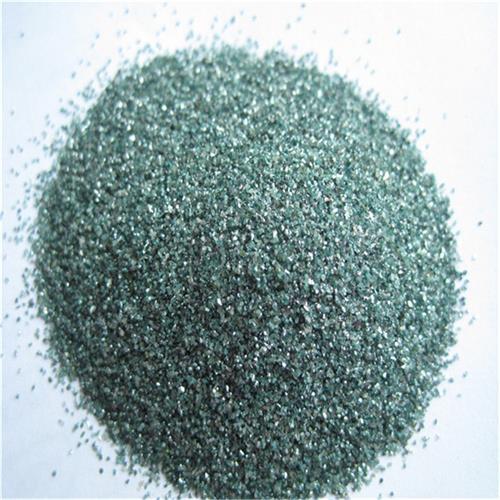

The diamond Micro finishing Film is a micro-abrasive product. It has diamond micron-graded grains which are electrostatically coated on high precision. It has 190 µm / 7,5 mil & 125 µm / 5 mil film with anti-slip back coating. Due to the sharp diamond structure and the robust resin bond, diamond micro finishing film gives a fast and aggressive cutting power, with a higher product strength and durability. It optimizes the finishing procedure. It has a reduction in abrasive consumption & it can be used dry with water emulsion.

The Diamond Micro Finishing Film has an extensive grit range from 125 µm to 15 µm. It offers a complete solution for the processing of harder materials, from rough to fine finishing.

Applications of diamond micro finishing film

The main applications for Diamond Micro finishing Film are grinding, micro finishing & superfinishing procedures of hard materials like carbides, sintered metal, cast materials, stone, and composite materials.

Features of diamond micro finishing film

The Diamond Micro Finishing Film is colour coded & back-printed to simply identify the abrasive grit required. It is available in Pressure Sensitive Adhesives such as discs, sheets & rolls. The Micron-graded diamond mineral delivers very close tolerance precision finishes for all the medium stock removal.

It enables slow abrasive feed rates & few steps which reduce abrasive costs. The Polyester film backing lets the roll be used dry or wet with the other surface lubricants. It has an exceptional roll for thermal spray finishing of contours and complex shapes. It is Colour coded to reduce the risk of error & mixing up abrasive grades. It is designed with a strong polyester film backing & sharp diamond mineral. The Diamond Micro Finishing Film Roll delivers fine finishes on hard metals like thermal spray coating carbides chilled iron & granite. The Diamond mineral is bonded to a polyester film backing. It is designed for finishing hard materials including thermal spray coatings, ceramics, chilled iron, granite, and others.