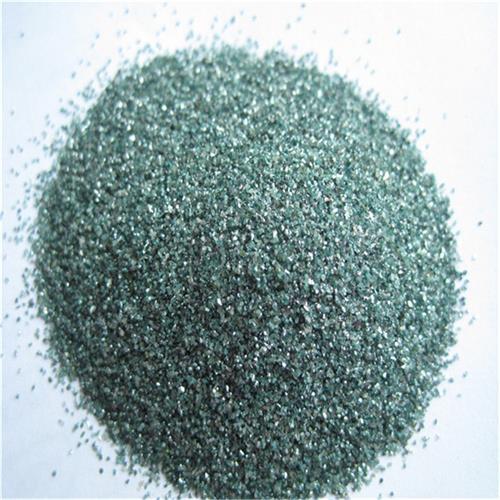

Black aluminum oxide media produced with a commitment to quality. Our customers love this product because of its excellent quality and exceptional efficacy.

To ensure that the given kind meets with recognised requirements, our organization manufactures it using quality-approved aluminum. This product can be utilized as refractory material in a variety of industries. This content is put through a number of tests by our vendors.

For polishing and etching, a typical abrasive is black aluminum oxide media. Aluminum oxide is a superior choice due to its unique qualities even though many various materials can be used for this.

Because of its numerous special characteristics, aluminum oxide is a better material than others. Aluminum oxide is a low iron content abrasive that prevents the surface of your part from rusting. Rust deposits can frequently lead to issues with future procedures.

Since it can be recovered and used for repeated blasting passes, aluminum oxide abrasive powder is a cost-effective blasting abrasive. Because aluminum oxide is a firmer abrasive than others, it creates less dust because there is less particle breakup.

When attempting to successfully impart an anchor pattern and deep etch for superior coating and paint adhesion, aluminum oxide is the best material to use. The removal of flaking paint, contaminants, mill scale, rust, and other surface-level pollutants from a substrate is another excellent use for it.

The powerful, cutting abrasive powder known as aluminum oxide is ideal for grinding metals with high tensile strengths. It is a good material for making refractory items because of its excellent thermal characteristics.