In the fast-evolving world of modern manufacturing, precision, speed, and consistency are critical. One technique that stands out for delivering all three is CNC turning services. From automotive to aerospace, medical to industrial machinery, CNC turning is trusted by manufacturers across industries to produce cylindrical parts with exceptional accuracy.

At Premium Parts Manufacturing Limited, we specialize in delivering high-precision CNC turning services using the latest equipment and a skilled team. Whether you’re in the early stages of development or in full-scale production, our solutions are designed to meet your custom part requirements with consistency and quality.

Let’s explore why CNC turning is such a valuable process, how it works, and why Premium Parts Manufacturing Limited is a trusted partner for businesses worldwide.

What is CNC Turning?

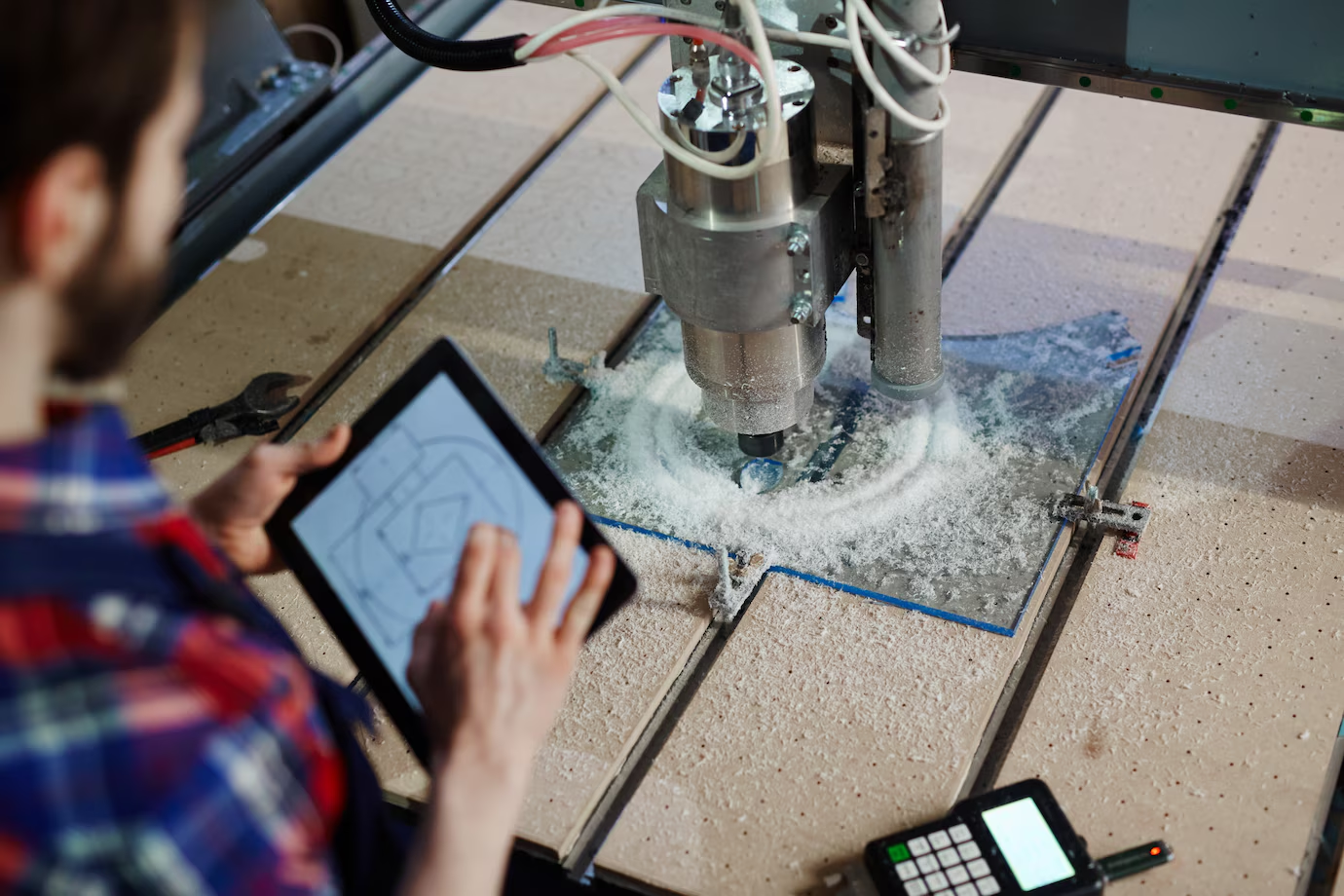

CNC (Computer Numerical Control) turning is a machining process where a cutting tool removes material from a rotating workpiece. The process is typically performed on a CNC lathe, and it’s ideal for creating round or cylindrical parts, such as shafts, bushings, bolts, and more.

The lathe spins the raw material while cutting tools shape it according to the design programmed into the machine. Because the process is automated, it offers extreme precision and repeatability, making it suitable for both prototyping and large-scale production.

Benefits of CNC Turning Services

1. Precision & Accuracy

CNC turning ensures that each part is machined to exact specifications, with tolerances as tight as ±0.001 inches. This level of precision is vital for industries like aerospace, defense, and medical devices.

2. High-Speed Production

CNC turning machines operate at high speeds and with minimal manual intervention, making them perfect for projects that demand quick turnarounds.

3. Repeatability

The computerized process allows manufacturers to produce large volumes of identical parts with virtually no deviation, making it ideal for mass production.

4. Cost-Effective Manufacturing

CNC turning is more affordable in the long run because it reduces waste, minimizes errors, and requires less human supervision.

5. Versatile Material Compatibility

CNC lathes can machine a wide range of materials including aluminum, stainless steel, brass, plastics, and titanium, making the service suitable for various industrial applications.

CNC Lathe Services at Premium Parts Manufacturing Limited

At Premium Parts Manufacturing Limited, we provide end-to-end CNC lathe services that are tailored to your needs. Our advanced turning centers are capable of handling complex geometries and producing parts in a wide range of sizes and materials.

Whether you need a single prototype or thousands of parts, we are equipped to deliver high-quality results at scale. Our engineering team collaborates closely with you from the design phase to final inspection, ensuring your parts meet all necessary standards.

We also offer multi-axis CNC turning, which combines turning and milling capabilities in one setup. This reduces the number of steps in the process, cuts lead time, and improves overall accuracy.

Applications of CNC Turning

CNC turning services are widely used across industries for producing parts such as:

-

Precision shafts

-

Custom fittings

-

Threaded components

-

Spacers and bushings

-

Valve components

-

Automotive pins and connectors

These parts are critical to the performance of larger assemblies and systems, which is why precision is non-negotiable.

Interlinking Our Solutions: Prototype CNC Machining Services

For clients still in the early stages of product development, we also offer prototype CNC machining services. This allows manufacturers to test fit, form, and functionality before committing to full-scale production.

By integrating CNC turning with prototyping services, Premium Parts ensures that product development is efficient, accurate, and cost-effective from the beginning to the end of the manufacturing cycle.

Why Choose Premium Parts Manufacturing Limited?

-

Advanced CNC Machines: Our fleet includes state-of-the-art CNC lathes capable of multi-axis turning.

-

Experienced Engineers: Our team brings years of hands-on experience across industries.

-

Strict Quality Control: We follow ISO-certified processes to ensure consistency and precision.

-

Fast Turnaround: We meet tight deadlines without compromising on quality.

-

Custom Solutions: From one-off prototypes to full-volume production, we tailor our services to your project.

FAQs About CNC Turning Services

Q1: What’s the difference between CNC turning and CNC milling?

CNC turning involves rotating the material while the cutting tool remains stationary. CNC milling is the opposite — the material stays stationary while the tool rotates and moves. Turning is ideal for round or cylindrical components.

Q2: Can CNC turning handle complex geometries?

Yes. With advanced CNC lathes and multi-axis setups, complex parts with features like threads, grooves, and tapers can be machined efficiently.

Q3: What materials can be used in CNC lathe services?

We can work with a wide range of materials including stainless steel, carbon steel, aluminum, brass, copper, titanium, and various plastics.

Q4: Do you offer CNC turning for prototypes?

Absolutely. Our prototype CNC machining services include CNC turning, giving you a quick and reliable way to test your designs.

Q5: How fast can I get my parts?

Turnaround times depend on the complexity and volume of your order, but we pride ourselves on delivering both rapid prototyping and full-scale production parts within tight schedules.

Final Thoughts

CNC turning remains one of the most reliable and cost-effective methods for manufacturing high-precision cylindrical parts. Whether you need a few custom prototypes or a thousand production-grade components, Premium Parts Manufacturing Limited has the expertise and technology to deliver.

Our CNC turning services, backed by advanced CNC lathe services and supported by prototype CNC machining services, offer the complete package for today’s manufacturers.