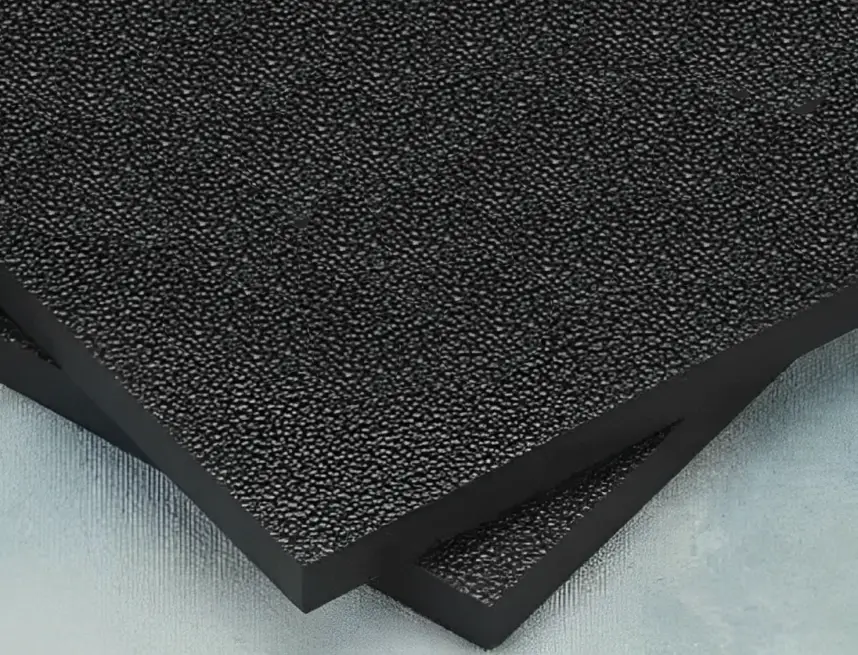

ABS plastic, short for Acrylonitrile Butadiene Styrene, is one of the most commonly used engineering plastics in the world. It’s known for its toughness, impact resistance, and versatility across a wide range of industries—from automotive to electronics, toys, and household goods.

In this article, we’ll explore what ABS materials is, its key properties, and why it’s so widely used in manufacturing and product design.

What is ABS Plastic?

ABS is a thermoplastic polymer, meaning it can be melted down and reshaped multiple times without degrading its quality. It is made by combining three monomers:

-

Acrylonitrile – offers chemical and heat resistance.

-

Butadiene – gives ABS its strength and impact resistance.

-

Styrene – provides a smooth, glossy finish and rigidity.

Together, these components give ABS a unique balance of durability, machinability, and aesthetics, making it ideal for both structural and decorative applications.

Key Properties of ABS Plastic

ABS plastic is known for several important characteristics:

-

High Impact Resistance: It can absorb shock without cracking or breaking, making it ideal for protective gear and casing.

-

Strength and Toughness: ABS is rigid yet resilient, suitable for both light and heavy-duty applications.

-

Machinability: It’s easy to cut, drill, sand, or glue, which makes it popular in prototyping and fabrication.

-

Good Aesthetic Finish: ABS has a natural glossy look and accepts paint and coatings well.

-

Electrical Insulation: It does not conduct electricity, which makes it safe for electrical enclosures.

-

Thermoformable: Being thermoplastic, it can be heated, molded, and cooled repeatedly without losing properties.

Why Do We Use ABS Plastic?

ABS is chosen for its balance of cost, performance, and usability. Here are some common reasons why industries prefer ABS over other materials:

-

Durability with Affordability

ABS offers strength and resistance comparable to higher-end plastics, but at a much lower cost. This makes it perfect for mass production without sacrificing quality. -

Ease of Processing

From injection molding to CNC machining, ABS is extremely easy to fabricate into complex shapes with tight tolerances. -

Versatility in Applications

Its strength-to-weight ratio and aesthetic appeal allow it to be used in:-

Automotive parts (dashboards, trims)

-

Consumer electronics (laptop shells, remote controls)

-

Toys (like LEGO bricks)

-

Pipes and fittings in plumbing systems

-

3D printing filament (due to its easy extrudability)

-

-

Chemical Resistance

ABS resists many acids, alkalis, and oils, making it suitable for industrial and chemical environments. -

Recyclability

As a thermoplastic, ABS can be recycled by melting and remolding, which supports sustainability goals in manufacturing.

Final Thoughts

ABS plastic is a versatile, strong, and cost-effective material that plays a vital role in modern manufacturing. Its excellent mechanical properties, ease of processing, and good finish make it a top choice for both functional and aesthetic components. Whether you’re designing a durable car part or a stylish gadget casing, petronthermoplast is likely the ABS material behind it.