In the ever-evolving automotive industry, the drive towards quality, safety, and reliability has never been more pronounced. One crucial process that plays a significant role in ensuring these standards are met is the Full Vehicle End of Line Test. This testing phase, conducted at the end of the manufacturing process, is essential for guaranteeing that every vehicle leaving the production line is ready for the road. In this comprehensive blog, we will explore the importance of Full Vehicle End of Line Tests, their key components, the benefits they offer, and how they contribute to the overall success of automotive manufacturing.

Understanding Full Vehicle End of Line Testing

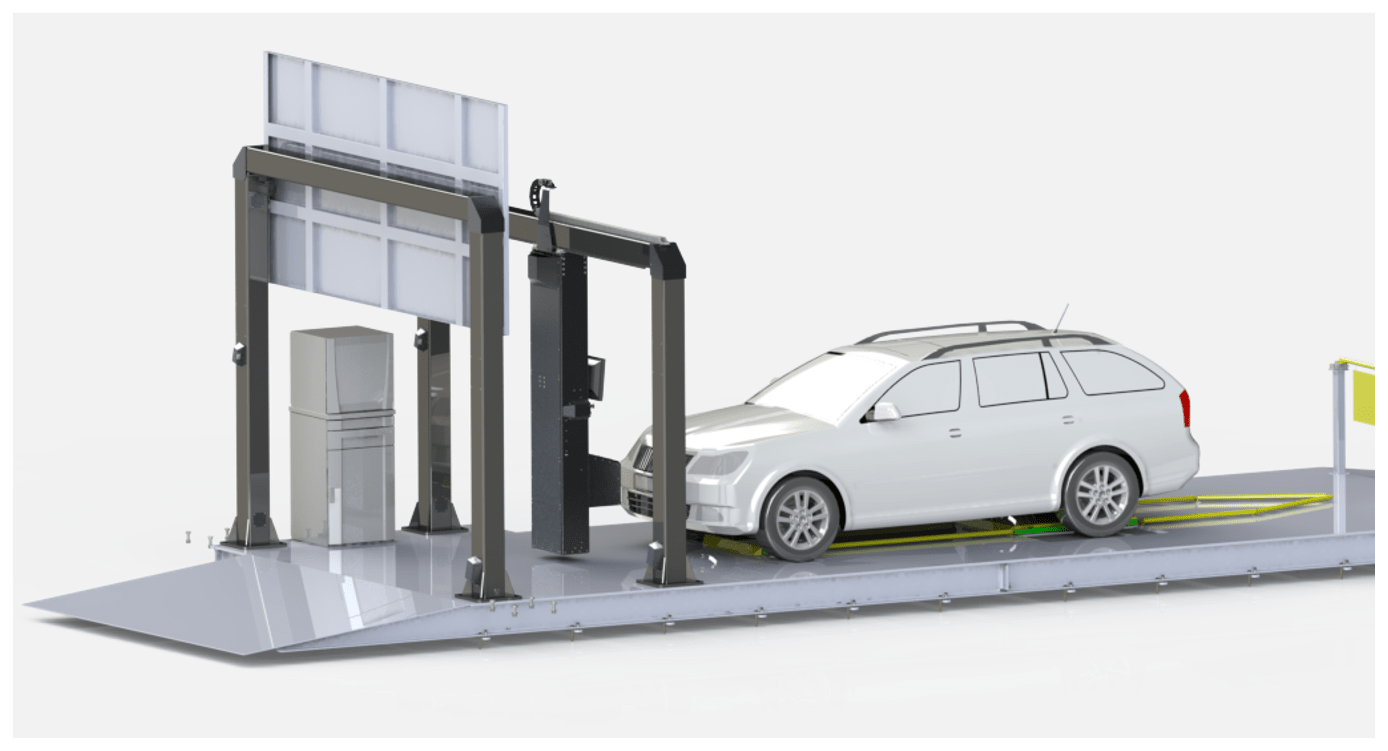

The Full Vehicle End of Line Test is a comprehensive series of inspections and checks performed on a vehicle once it has completed the assembly process. This testing phase occurs at the end of the production line, hence the name, and is designed to ensure that the vehicle meets all required quality and safety standards before it is shipped to dealerships and ultimately to customers.

During this phase, various systems and components of the vehicle are meticulously examined to detect any defects or issues that might have arisen during manufacturing. This includes everything from mechanical and electrical systems to safety features and overall vehicle performance. The goal is to identify and rectify any problems before the vehicle reaches the consumer.

Why Full Vehicle End of Line Testing is Essential

The Full Vehicle End of Line Test is a critical component of the automotive manufacturing process for several reasons:

- Ensures Quality Control: Quality assurance is a fundamental aspect of vehicle manufacturing. Full Vehicle End of Line Testing helps manufacturers maintain high standards by thoroughly checking each vehicle to ensure it meets the required specifications. By catching potential defects at this stage, manufacturers can prevent subpar vehicles from reaching the market.

- Confirms Safety Compliance: Safety is a top priority in the automotive industry. The End of Line Test verifies that all safety features, such as airbags, seatbelts, and braking systems, are functioning correctly. This ensures that the vehicle adheres to safety regulations and provides protection for the driver and passengers.

- Validates Performance: The End of Line Testing phase assesses the vehicle’s performance across various parameters, including engine functionality, transmission smoothness, and overall driving dynamics. This validation process ensures that the vehicle performs as expected and delivers a positive driving experience.

- Adheres to Regulatory Standards: Different markets have specific regulations and standards that vehicles must meet. The Full Vehicle End of Line Test helps ensure that vehicles comply with these regulations, facilitating their acceptance in various regions and countries.

- Reduces Post-Sale Issues: Identifying and addressing issues during the End of Line Test is more cost-effective than dealing with defects after the vehicle has been sold. By addressing potential problems before the vehicle reaches dealerships, manufacturers can reduce the risk of costly recalls and enhance their brand reputation.

Key Components of Full Vehicle End of Line Testing

Full Vehicle End of Line Testing involves a thorough examination of multiple aspects of a vehicle. Here are some key components typically included in this process:

- Visual Inspection: A detailed visual inspection is the first step in the End of Line Testing process. Technicians check the vehicle’s exterior and interior for any cosmetic defects, ensure that all components are properly installed, and verify that there are no visible signs of damage. This step helps catch any issues that might affect the vehicle’s overall appearance and functionality.

- Functional Testing: This component involves verifying that all vehicle systems and features function correctly. Key areas of functional testing include:

- Engine: The engine is tested for start-up, idle performance, acceleration, and overall functionality. This ensures that the engine operates smoothly and efficiently.

- Transmission: Transmission functionality is assessed by checking gear shifts and responsiveness. Smooth gear transitions are crucial for optimal driving performance.

- Braking System: The braking system is tested for stopping power and responsiveness. Proper brake function is essential for vehicle safety and performance.

- Electrical Systems: Electrical systems, including lighting, infotainment, navigation, and other components, are tested to ensure they operate as intended.

- Safety Features Check: Ensuring that safety features are functioning correctly is a critical part of Full Vehicle End of Line Testing. This includes checking airbags, seatbelts, anti-lock braking systems (ABS), and other safety-related components to ensure they meet safety standards and regulations.

- Emissions Testing: Vehicles must comply with specific emissions standards to minimize their environmental impact. The End of Line Testing process includes checking exhaust emissions to ensure that the vehicle meets environmental regulations.

- Road Testing: Some manufacturers include a road test as part of the End of Line Testing process. This involves driving the vehicle to assess its overall performance, handling, and comfort. Road testing helps identify any issues that may not be apparent through other testing methods.

- Diagnostic Testing: Advanced diagnostic tools are used to identify underlying issues that may not be visible through visual or functional testing alone. These tools help detect problems with electronic control units (ECUs) and other complex systems.

Implementing an Effective Full Vehicle End of Line Testing Process

To ensure that Full Vehicle End of Line Testing is effective, manufacturers should consider several key factors:

- Investment in Testing Equipment: High-quality testing equipment and diagnostic tools are essential for accurate and efficient testing. This includes tools for mechanical, electrical, and emissions testing.

- Skilled Technicians: Trained and experienced technicians play a crucial role in the End of Line Testing process. They must be knowledgeable about the specific systems and components of the vehicles they are testing to ensure thorough and accurate inspections.

- Standard Operating Procedures (SOPs): Developing and adhering to detailed SOPs ensures that the testing process is consistent and comprehensive. This includes clearly defined testing procedures and criteria for passing or failing each test.

- Data Management: Proper documentation and data management are vital for tracking test results and identifying trends or recurring issues. This information can be used for quality control and continuous improvement.

- Integration with Production: Full Vehicle End of Line Testing should be seamlessly integrated into the production line to minimize delays and ensure that every vehicle undergoes the necessary tests before leaving the factory.

Benefits of Full Vehicle End of Line Testing

The benefits of implementing a robust Full Vehicle End of Line Testing process are numerous:

- Enhanced Customer Satisfaction: By ensuring that each vehicle meets high-quality standards, manufacturers can enhance customer satisfaction and build trust in their brand. Customers are more likely to be satisfied with a vehicle that performs well and meets their expectations.

- Reduced Warranty Claims: Thorough testing reduces the likelihood of defects and issues that could lead to warranty claims. This helps manufacturers save costs associated with warranty repairs and enhances their overall profitability.

- Improved Brand Reputation: Consistently delivering high-quality vehicles strengthens a manufacturer’s reputation and can lead to increased market share and customer loyalty. A strong brand reputation is crucial for long-term success in the competitive automotive industry.

- Regulatory Compliance: Meeting regulatory standards is essential for avoiding legal issues and ensuring that vehicles can be sold in various markets without complications. Full Vehicle End of Line Testing helps manufacturers navigate complex regulatory requirements and achieve compliance.

- Cost Efficiency: Addressing potential issues during the End of Line Testing phase is more cost-effective than dealing with defects after the vehicle has been sold. This approach reduces the risk of costly recalls and helps manufacturers manage production costs more effectively.

Conclusion

Full Vehicle End of Line Testing is a vital process in the automotive manufacturing industry, ensuring that every vehicle meets the highest standards of quality, safety, and performance. By conducting thorough inspections and tests at the end of the production line, manufacturers can deliver reliable and well-functioning vehicles to consumers. This process not only enhances customer satisfaction but also helps manufacturers reduce costs, comply with regulations, and build a strong brand reputation. For automotive companies committed to excellence, implementing an effective Full Vehicle End of Line Testing process is essential for achieving long-term success and maintaining a competitive edge in the industry.