The most common metallographic abrasives are

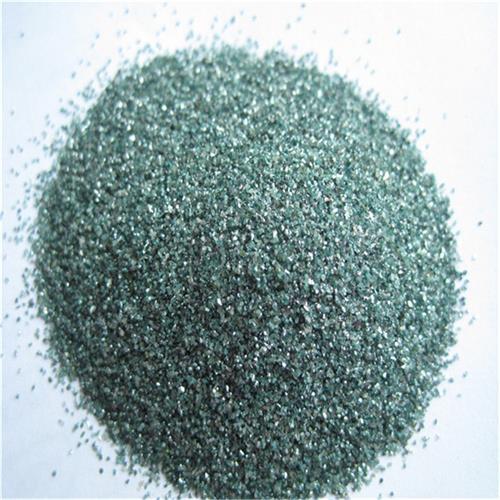

Silicon Carbide

It is a manufactured abrasive produced by a higher temperature reaction between silica & carbon. It has a hexagonal crystal structure and it has a hardness of about 2500 HV. It is a perfect abrasive for cutting & grinding because of its hardness & very sharp edges. It is somewhat brittle, so it cleaves easily to produce sharp new edges. It is an excellent abrasive for making the most of cutting rates while minimizing surface & subsurface damage. For metallographic preparation, these abrasives are used in abrasive blades & for coated abrasive grinding papers ranging from coarse 60 grit to fine 1200 grit sizes.

The metallographic abrasive paper is designed so that the abrasive will have a very large number of cutting points. This is achieved by positioning the abrasive particles around normal to the backing. The coated abrasives are not quite coplanar; thus, the papers produce the maximum efficiency because the new abrasive is visible as the old abrasive breaks down.

The Metallographic Abrasive Grinding Consumables

Alumina

Alumina is a naturally occurring material. It exists in either the soft gamma or harder alpha phase. Alumina abrasives are used as a final polishing abrasive because of their higher hardness and durability. The alumina breaks down relatively easily into submicron or colloidal particles. The larger coated grit sizes of alumina are commercially available, but, they are not ideal for metallographic applications since they become dull, resulting in low cut rates and high surface and subsurface damage.

Diamond

Is the hardest material. It has a cubic crystal structure, and it is available as a natural or an artificial product. Although it would be ideal for coarse grinding, the price makes it a very inefficient material for anything except hard ceramics. For all metallographic applications, polycrystalline diamond is recommended as a very rough polishing abrasive.