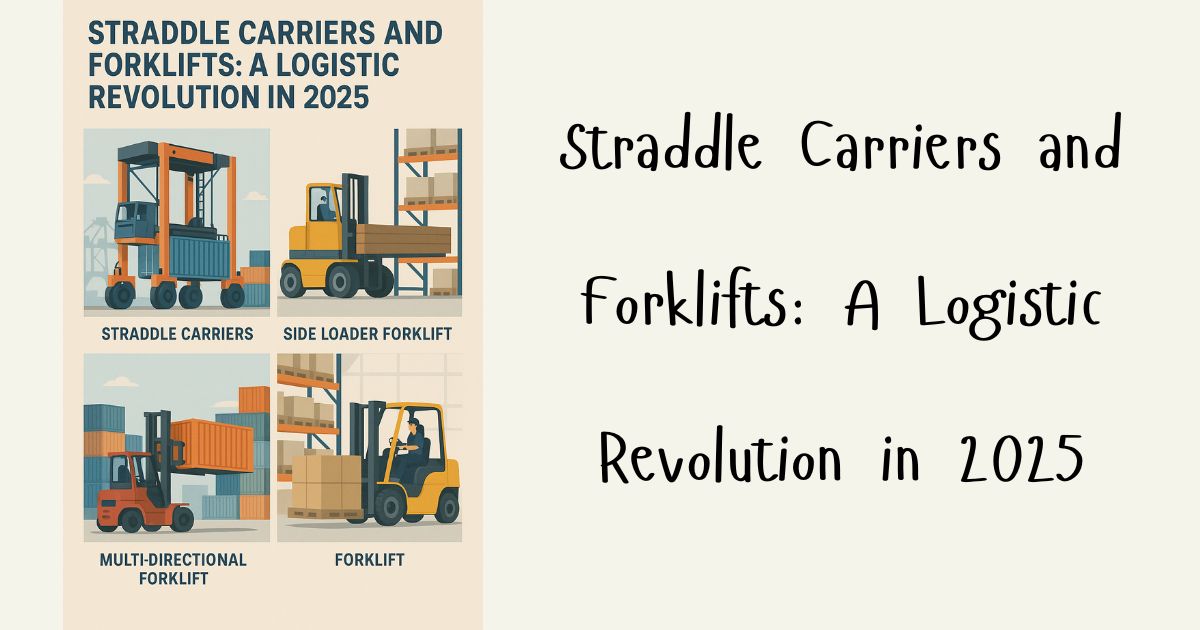

In 2025, the logistics and material handling sector is experiencing a significant change, propelled by advancements in heavy equipment and warehouse automation. Among the standout innovations reshaping the sector are Straddle Carriers, specialized transport vehicles that have emerged as critical components in container terminals and intermodal freight operations. Alongside them, advancements in forklift design—particularly with the introduction of specialized units like the Side Loader Forklift—are redefining how companies manage bulky and long-load materials in confined spaces. This combination of high-capacity handling and directional versatility marks a new chapter in operational efficiency for logistics.

The Changing Landscape of Logistics

Global trade continues to expand in scale and complexity, demanding faster, safer, and more efficient cargo handling solutions. Urbanization, e-commerce growth, and sustainability pressures are compelling industries to reimagine their supply chains. As warehouses grow vertically and transportation hubs deal with tighter spaces, traditional handling methods struggle to keep pace. The demand for agility, higher throughput, and minimal downtime is prompting a shift toward smarter, more specialized logistics equipment.

Straddle Carriers: Giants of Port Logistics

Straddle Carriers are large, mobile machines primarily used in shipping terminals to lift and transport containers. These towering vehicles can pick up and carry containers without the need for cranes or additional lifting devices. Their primary strength is their capability to move containers efficiently across port terminals.

In 2025, Straddle Carriers have evolved to become more fuel-efficient and environmentally friendly, often utilizing hybrid or fully electric power systems. Automation is another significant leap forward—autonomous navigation systems allow these carriers to operate with minimal human input, reducing labor costs and enhancing safety. Integration with port logistics software ensures optimal routing and container tracking, minimizing delays and congestion at critical points in the supply chain.

Furthermore, modern straddle carriers are equipped with real-time diagnostics and IoT-enabled sensors, allowing for predictive maintenance and minimal equipment downtime. These innovations contribute directly to lowering the total cost of ownership and enhancing the overall speed of cargo throughput.

Forklifts: Evolving from Simple Lifters to Smart Machines

Forklifts remain essential in nearly every logistics environment, from distribution centers to manufacturing plants. However, the forklifts of 2025 are far removed from their early 20th-century predecessors. They have become smarter, safer, and more specialized.

Today’s forklifts come in a wide variety of designs tailored to specific environments and material types. One of the most significant advances has been the integration of smart technologies such as sensors, cameras, and AI-based navigation systems. These features improve safety in busy warehouses by helping operators avoid collisions and detect anomalies.

The use of electric power in forklifts has become more prevalent, aligning with global goals for carbon neutrality. Battery life has also improved significantly, allowing forklifts to operate longer between charges without sacrificing performance. AGVs and autonomous mobile robots are starting to enhance traditional forklifts, which helps optimize operations in high-volume logistics environments.

Multi-Directional Forklifts: The New Standard for Versatility

A major highlight in forklift innovation is the Multi-Directional Forklift, which is transforming operations that involve long or bulky loads. These forklifts can move forward, backward, and sideways, offering unparalleled maneuverability in tight spaces. They’re ideal for handling materials such as timber, piping, and sheet metal—items that are awkward for conventional forklifts to manage.

In environments where floor space is at a premium, Multi-Directional Forklifts reduce the need for wide aisles, allowing facilities to store more products in the same footprint. Moreover, this directional flexibility reduces the time spent repositioning loads, significantly boosting overall productivity.

Many of these models are now fitted with ergonomic controls, advanced safety features, and energy-efficient powertrains, making them a wise investment for businesses looking to modernize their material handling without compromising on safety or environmental goals.

Integration and Automation: The Next Frontier

While individual machine innovation is critical, the real revolution lies in how these machines integrate with broader logistical ecosystems. Warehouse Management Systems and ERP software are now directly linked to handling equipment, including forklifts and straddle carriers. This allows real-time decision-making based on live data—automatically rerouting equipment, optimizing loads, and reducing bottlenecks.

In smart warehouses and ports, machines communicate with each other and with central control systems, leading to a higher level of coordination. For example, a straddle carrier can alert a warehouse forklift that a container has arrived, prompting immediate action and reducing idle time. Predictive analytics powered by AI can further enhance this coordination by forecasting equipment maintenance needs or supply chain disruptions before they occur.

Sustainability and the Green Logistics Movement

Environmental sustainability has become essential in the logistics industry. Businesses are facing growing demands to cut emissions, decrease energy use, and lessen their environmental impact. The upcoming generation of logistics machinery is being developed with a strong emphasis on sustainability.

Many new forklifts and straddle carriers are now equipped with hybrid and electric drivetrains. Logistics centers are incorporating renewable energy sources, and recyclable and biodegradable materials are being utilized in the manufacturing of equipment. Furthermore, manufacturers are concentrating on life cycle assessment and circular economy approaches to ensure that equipment can be reused, repurposed, or recycled once it has reached the end of its lifespan.

Conclusion: A Revolution Rooted in Technology

The logistics revolution of 2025 is not just about moving goods faster—it’s about moving them smarter. The rise of automated, versatile, and sustainable machinery like Straddle Carriers and specialized forklifts is setting new benchmarks in efficiency and safety.

Innovative solutions such as the Side Loader Forklift and Multi-Directional Forklift are tackling unique handling issues, while intelligent, self-operating straddle carriers are taking charge at ports. Logistics managers are now more prepared than ever to fulfill the requirements of a fast-changing global marketplace. As digitalization and automation increasingly integrate with mechanical advancements, the logistics sector is set for even more significant improvements in productivity, sustainability, and resilience in the future.