The FG Falcon is praised for its combination of performance and comfort, a feature greatly influenced by its power steering system. At the heart of this system lies the power steering pump, an essential component that enables easy steering and smooth handling. Fg Falcon power steering pump replacement is responsible for circulating hydraulic fluid, thus reducing the effort required to turn the steering wheel. Regular maintenance and timely power steering pump replacement are essential to ensure optimal vehicle performance. Whether navigating city streets or cruising on the motorway, the effectiveness of the power steering pump plays a significant role in the overall driving experience.

Signs of a Failing Power Steering Pump

Recognising the symptoms of a failing power steering pump is crucial for vehicle safety and performance. One of the most common signs is a whining or groaning noise when turning the steering wheel. Another indicator is difficulty in steering, particularly at lower speeds, where the steering wheel may feel unusually stiff or resistant.

Fluid leaks underneath the vehicle can signal pump issues, often accompanied by a noticeable drop in power steering fluid levels. Additionally, if the steering wheel vibrates or the car becomes more challenging to manoeuvre, these could be symptoms of a deteriorating power steering pump. Addressing these signs promptly can prevent more extensive damage to the steering system.

Tools Required for Replacement

Replacing the power steering pump in an FG Falcon requires specific tools to ensure a smooth and efficient process. Having the right equipment on hand helps prevent complications and ensures proper installation.

Socket Set and Spanners

A socket set and spanners are necessary for loosening and tightening bolts securing the power steering pump. These tools provide the leverage needed to remove and install components securely.

Screwdrivers for Component Removal

Screwdrivers help remove and secure various smaller components connected to the pump. They are also helpful for detaching hoses, brackets, and electrical connections.

Pulley Puller for Safe Removal

A pulley puller is crucial for safely removing the pulley from the old pump. This tool prevents damage to the pulley and ensures it can be reused or replaced without complications.

Personal Protective Equipment

Safety should always be a priority. Wearing gloves and safety glasses protects against hydraulic fluid exposure and prevents injuries from sharp or heavy components.

Drip Tray for Fluid Management

A drip tray helps catch any hydraulic fluid that may spill during the replacement process. Proper fluid management helps maintain a clean workspace and prevents environmental contamination.

Preparing the Vehicle

Begin by parking the FG Falcon on a flat surface, ensuring the handbrake is fully engaged. Disconnect the battery to eliminate any risk of electrical issues during the procedure. Using a hydraulic jack, elevate the vehicle and place it securely on jack stands to provide safe access to the undercarriage. Removing the front wheels to gain better visibility and maneuverability is advisable.

Clean the area around the power steering pump to prevent dirt or debris contaminating the system. A drip tray will catch any hydraulic fluid that might spill during the process, maintaining a tidy work environment. Personal protective equipment, such as gloves and safety glasses, should be worn to ensure safety throughout the operation.

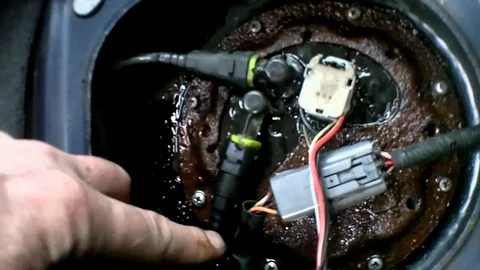

Removing the Old Power Steering Pump

To remove the old power steering pump, locate it and loosen the drive belt.

- Disconnect the power steering hoses, being cautious of escaping fluid.

- Carefully unbolt the pump from its mounting bracket and extract it from the vehicle.

- Some components may be challenging, so patience and the appropriate tools are crucial.

- Regular maintenance and inspection can help catch these issues early, ensuring your power steering system remains in optimal condition.

- It’s advisable to consult a qualified mechanic if you notice any of these warning signs to avoid potentially costly repairs in the future.

Inspecting Related Components

With the old pump removed, the next step involves thoroughly inspecting the related components within the power steering system. The hoses should be checked for any signs of cracking, leaks, or wear, as these could compromise the system’s performance.

The drive belt must be examined for fraying, glazing, or any other damage that might affect its function. Additionally, the pulley attached to the pump should be scrutinised for any signs of misalignment or wear. If the pulley is not in good condition, it could lead to the premature failure of the new pump.

Ensuring that all these components are in optimal condition will contribute to the longevity and efficiency of the newly FG Falcon power steering pump replacement. Addressing any issues at this stage can save time and prevent further complications.

Installing the New Power Steering Pump

Begin the installation by aligning the new power steering pump with the mounting bracket. Carefully secure it, ensuring all bolts are tightened to the manufacturer’s specifications. Reconnect the power steering hoses, ensuring they are firmly attached and leak-free. Next, reinstall the drive belt, ensuring it is correctly aligned to prevent undue stress on the system.

Double-check all connections to verify that everything is adequately secured. Proper alignment and secure connections are crucial to avoid operational issues and to ensure the system functions efficiently.

Bleeding the Power Steering System

Bleeding the power steering system is essential to removing any trapped air, ensuring optimal performance. To begin, fill the power steering reservoir with the recommended hydraulic fluid. With the engine running, turn the steering wheel fully to the left and right, repeating this several times. This action helps expel air bubbles trapped in the system.

It is advisable to periodically check the fluid level during this process and top up as necessary. The sound of whirring or groaning from the pump typically indicates remaining air in the system. Continue bleeding until such noises cease and the steering response becomes smooth. Regularly monitor the power steering fluid level and inspect for potential leaks throughout the procedure.

Testing the New Installation

A thorough inspection is necessary once the new power steering pump is installed and the system is bled. Start the engine and check for leaks or unusual noises around the pump area.

Steering Wheel Movement Test

Turn the steering wheel from lock to lock and observe its response. The movement should be smooth, without resistance or vibrations, indicating proper fluid circulation and pump function.

Monitoring Fluid Levels

Verify that the power steering fluid level remains stable during operation. A sudden drop in fluid levels could signal a leak or incomplete system bleeding.

Identifying Potential Issues

If irregularities such as stiffness, whining noises, or inconsistent steering response occur, air may be trapped in the system, or there may be an installation issue. Rebleeding the system may be necessary.

Ensuring Proper Functionality

Proper testing ensures that the replacement has been successful. Confirming smooth steering operation and stable fluid levels guarantees the system functions correctly.

Common Mistakes to Avoid

One frequent error is improper bleeding of the power steering system, leading to inefficient steering and potential damage. Another mistake is neglecting to securely tighten all bolts, which can result in mechanical failures and unsafe driving conditions. Misalignment of the drive belt is also a common issue that can cause undue stress on the pump and other components, leading to premature wear.

Overlooking the inspection of parts, such as hoses and the pulley, can compromise the system’s effectiveness. Additionally, failing to use the correct type of hydraulic fluid can affect the pump’s performance and longevity. Attention to these details is crucial for a successful replacement.

Maintaining the Power Steering System

Proper upkeep of the power steering system in an FG Falcon involves several routine checks and timely interventions. Regularly inspecting and maintaining the power steering fluid levels is paramount.

Utilising the correct hydraulic fluid as the manufacturer recommends will ensure optimal performance and longevity of the system. Monitoring the hoses for wear, leaks, or cracking is equally essential, as compromised hoses can lead to fluid loss and steering issues. The drive belt should be periodically examined for fraying, glazing, or other damage, as these issues can impact the effectiveness of the power steering pump.

Maintaining Its Integrity

Ensuring the belt is correctly aligned and appropriately tensioned will help prevent undue stress on the pump and associated components. Cleaning the reservoir and the pump area from accumulated dirt and debris can prevent contaminants from entering the system, thus maintaining its integrity.

Using the vehicle’s service manual to guide the recommended maintenance schedule can help keep the power steering system in top condition. Regular servicing by a qualified technician can identify potential problems before they escalate, ensuring that the FG Falcon remains safe and reliable on the road. Adhering to these maintenance practices can significantly extend the lifespan of the power steering system, enhancing the overall driving experience.

Conclusion

Fg Falcon power steering pump replacement is crucial to ensure the vehicle’s optimal performance and safety. Identifying and addressing the early signs of pump failure can prevent more severe issues down the line. The replacement process can be executed efficiently with the correct tools and a systematic approach. Ensuring that all components are inspected and properly installed will contribute to the longevity of the new pump. Additionally, regular maintenance of the power steering system will sustain its functionality and enhance the driving experience. By adhering to these guidelines, the FG Falcon will continue to provide smooth and reliable steering, ensuring a safer and more enjoyable journey.

FAQs

What are the signs that my fg Falcon power steering pump replacement?

Common symptoms include whining or groaning when turning the wheel, difficulty steering, fluid leaks, and inconsistent power assist. If you fg Falcon power steering pump replacement, inspecting the pump and fluid levels can help determine if a replacement is necessary.

How do I replace the power steering pump on an FG Falcon?

Start by disconnecting the battery and removing the ram air snorkel, thermo fans, and fan belt to access the pump. Disconnect the high-pressure power steering line and the low-pressure return hose, then unscrew the mounting bolts to remove the old pump. Install the new pump, reconnect the hoses, secure the bolts, and refill the power steering fluid. A detailed step-by-step guide can be found here.

What should I consider when choosing a replacement power steering pump?

Check the pump’s pressure rating, mounting style, and hose connections to ensure compatibility with your FG Falcon model. Opt for a high-quality pump from a reputable manufacturer to ensure durability and smooth operation. Proper installation and fluid maintenance will help extend the new pump’s lifespan.