Choosing the right Centreless Grinding Machine Manufacturer is crucial for any business that relies on precision grinding for its products. The performance, reliability, and quality of your grinding machines can significantly impact your production efficiency, product quality, and ultimately, your bottom line. But how do you know when it’s time to switch to a new manufacturer? In this comprehensive guide, we will explore the key factors to consider, the signs that indicate it might be time to make a change, and the benefits of finding the right manufacturer for your business needs.

Understanding Centreless Grinding and Its Importance

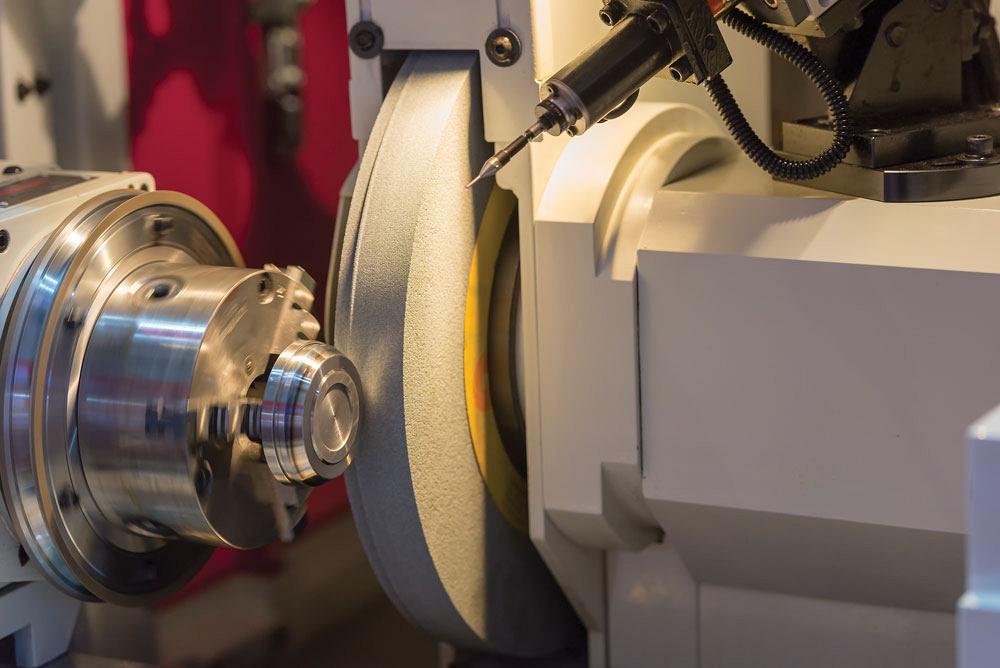

Centreless grinding is a machining process that involves the removal of material from a workpiece by means of abrasive cutting. Unlike traditional cylindrical grinding, where the workpiece is held between centers, centreless grinding holds the workpiece between two rotary wheels, a stationary wheel, and a movable wheel that applies pressure to the workpiece. This process is widely used in manufacturing industries for producing high-precision components, such as automotive parts, aerospace components, and medical devices.

The precision and efficiency of centreless grinding machines are paramount. High-quality machines can achieve tight tolerances, smooth finishes, and high throughput, making them indispensable in many manufacturing processes. Therefore, the choice of Centreless Grinding Machine Manufacturers plays a critical role in ensuring consistent and reliable production.

Key Factors to Consider When Evaluating Manufacturers

When evaluating Centreless Grinding Machine Manufacturers, several factors should be taken into account to ensure you make the right choice for your business. Here are some essential considerations:

- Quality and Precision The primary purpose of centreless grinding machines is to achieve high precision and quality. Ensure that the manufacturer you are considering has a reputation for producing machines that meet or exceed industry standards. Look for manufacturers that use high-quality materials and components, and have rigorous quality control processes in place.

- Technological Advancements The manufacturing industry is constantly evolving, with new technologies and innovations emerging regularly. A good manufacturer should be at the forefront of these advancements, offering machines that incorporate the latest technologies, such as automation, CNC controls, and advanced monitoring systems. This can significantly enhance the performance and efficiency of your grinding operations.

- Customization and Flexibility Every business has unique needs and requirements. A manufacturer that offers customization options and flexible solutions can provide machines that are tailored to your specific applications. This can lead to better performance, reduced downtime, and higher productivity.

- After-Sales Support and Service Reliable after-sales support and service are crucial when investing in centreless grinding machines. Look for manufacturers that offer comprehensive support, including installation, training, maintenance, and repair services. A responsive and knowledgeable support team can help you address any issues quickly, minimizing disruptions to your production.

- Reputation and Track Record Research the reputation and track record of the manufacturers you are considering. Look for customer reviews, testimonials, and case studies to gain insights into their performance and reliability. A manufacturer with a proven track record of delivering high-quality machines and excellent customer service is more likely to meet your expectations.

- Cost and Return on Investment While cost is an important factor, it should not be the sole determinant in your decision. Consider the overall value and return on investment (ROI) that the manufacturer can provide. A higher initial investment in a high-quality machine can lead to long-term savings through improved efficiency, reduced downtime, and lower maintenance costs.

Signs It Might Be Time to Switch Manufacturers

Even if you have been working with a particular manufacturer for a while, there may come a time when it is necessary to switch to a new supplier. Here are some signs that indicate it might be time to make a change:

- Frequent Machine Breakdowns If your current machines are experiencing frequent breakdowns and require constant repairs, it may be a sign that the quality and reliability of the equipment are not up to par. This can lead to significant downtime, lost productivity, and increased maintenance costs.

- Inconsistent Quality and Precision Variability in the quality and precision of your products can be a major issue, especially in industries where tight tolerances are critical. If you are consistently facing issues with the accuracy and finish of your components, it may be time to evaluate other manufacturers who can provide more reliable and precise machines.

- Lack of Technological Advancements If your current manufacturer is not keeping up with technological advancements and offering outdated machines, you may be missing out on opportunities to improve your production efficiency and capabilities. Switching to a manufacturer that offers state-of-the-art machines can give you a competitive edge.

- Poor After-Sales Support After-sales support is essential for the smooth operation of your grinding machines. If you are facing difficulties in getting timely support, parts, or maintenance services from your current manufacturer, it can lead to prolonged downtime and production delays. A manufacturer with a strong support network can help you avoid these issues.

- High Operational Costs If your operational costs are rising due to inefficient machines, frequent repairs, or high maintenance expenses, it may be worth considering a switch to a manufacturer that can provide more cost-effective solutions. Newer, more efficient machines can lead to significant savings in the long run.

- Negative Feedback from Your Team Your team’s feedback can provide valuable insights into the performance and reliability of your machines. If your operators and maintenance staff are consistently reporting issues and expressing dissatisfaction with the current equipment, it may be a clear indication that a change is needed.

The Benefits of Switching to the Right Manufacturer

Switching to the right Centreless Grinding Machine Manufacturer can bring numerous benefits to your business. Here are some of the key advantages:

- Improved Production Efficiency High-quality, reliable machines can significantly enhance your production efficiency. With fewer breakdowns and more consistent performance, you can achieve higher throughput and meet production targets more effectively.

- Enhanced Product Quality Precision and consistency are crucial in manufacturing. By choosing a manufacturer that provides machines with superior precision and quality, you can ensure that your products meet the highest standards and exceed customer expectations.

- Access to Advanced Technologies Working with a manufacturer that incorporates the latest technologies into their machines can provide you with new capabilities and improve your overall production process. Automation, advanced monitoring systems, and CNC controls can streamline operations and reduce the risk of errors.

- Reduced Downtime Reliable machines with robust after-sales support can minimize downtime and keep your production running smoothly. Quick access to spare parts, timely maintenance, and responsive technical support can prevent prolonged disruptions.

- Lower Operational Costs Investing in high-quality, efficient machines can lead to lower operational costs in the long run. Reduced maintenance requirements, lower energy consumption, and fewer repairs can result in significant savings over the lifespan of the equipment.

- Increased Flexibility and Customization A manufacturer that offers customized solutions can provide machines tailored to your specific needs, enhancing your production capabilities and allowing you to take on more complex projects.

- Better Support and Collaboration Establishing a strong partnership with a reputable manufacturer can lead to better support and collaboration. You can benefit from their expertise, receive valuable insights, and work together to optimize your production processes.

How to Evaluate Potential New Manufacturers

If you decide it’s time to switch Centreless Grinding Machine Manufacturers, it’s important to conduct thorough research and evaluation to ensure you choose the right supplier. Here are some steps to help you in the evaluation process:

- Identify Your Requirements Start by identifying your specific requirements and goals. Consider factors such as the types of materials you work with, the required precision and tolerances, production volumes, and any special features or capabilities you need in the machines.

- Research Potential Manufacturers Conduct comprehensive research on potential manufacturers. Look for information on their product offerings, technological advancements, customer reviews, and industry reputation. Utilize online resources, industry publications, and trade shows to gather information.

- Request Demos and Trials Request demos and trials of the machines you are considering. Hands-on experience can provide valuable insights into the performance, ease of use, and reliability of the equipment. Pay attention to how well the machines meet your requirements and how comfortable your operators are with them.

- Evaluate After-Sales Support Assess the after-sales support and service offered by the manufacturers. Inquire about the availability of spare parts, response times for technical support, and the range of services they provide. A manufacturer with strong support capabilities can help you address any issues quickly and efficiently.

- Check References and Testimonials Request references and testimonials from other customers who have used the manufacturer’s machines. This can give you a better understanding of their performance, reliability, and customer satisfaction. Reach out to these references to ask about their experiences and any challenges they faced.

- Consider Total Cost of Ownership Evaluate the total cost of ownership (TCO) of the machines, including the initial purchase price, maintenance costs, energy consumption, and expected lifespan. Compare the TCO of different manufacturers to determine which offers the best value for your investment.

- Negotiate Terms and Conditions Once you have identified a potential manufacturer, negotiate the terms and conditions of the purchase. Ensure that you have a clear understanding of the warranty, service agreements, delivery timelines, and any customization requirements.

Conclusion

Switching Centreless Grinding Machine Manufacturers is a significant decision that can have a profound impact on your business. By carefully evaluating your current situation, identifying key factors to consider, and conducting thorough research, you can make an informed choice that aligns with your production goals and requirements. The right manufacturer can provide you with high-quality, reliable machines that enhance your production efficiency, improve product quality, and reduce operational costs. Don’t hesitate to make a change if it means achieving better performance and greater success for your business.

Also Read: Is CNC Cylindrical Grinding Machine Programming Difficult?