Introduction to HDPE Sheet: The Modern Material Marvel

The polymer known as high-density polyethylene (HDPE), is a thermoplastic (meaning it becomes pliable when heated) consisting of either 2 or 4 monomers. HDPE sheets are becoming increasingly popular due to their excellent chemical resistance, low moisture absorption, and incredible resistance to impact Whether it’s the durable HDPE sheets black used outdoors and in industrial applications, or the clean versatile white HDPE sheet in food services, or the vibrant blue HDPE sheet that can be found in marine applications; the way HDPE is shifting industries’ approach to strength and durability and how long they can rely on their suppliers is remarkable.

Manufacturing Process and Properties of HDPE Sheet

HDPE sheets are produced through an extrusion process that melts HDPE resin into flat sheets of varying thicknesses as dictated by the ultimate end-use. HDPE sheets may have characteristics resulting in differences in density and flexibility The most significant and beneficial characteristic of an HDPE sheet is it being impact and harsh chemical resistant These HDPE sheets black a go-to option for heavy-duty applications. As a bonus, HDPE has a very low coefficient of friction This means when used for different mechanical applications that incorporate sliding parts, this attribute will not inhibit the ability to initiate and maintain motion. The properties of HDPE provide durability at the cost of virtually nothing in terms of weight. Therefore, movement and installation is relatively easy and not cost prohibitive.

Common Applications of HDPE Sheet Across Industries

HDPE sheets are used worldwide in many different industries due to their vast application range. Sheet is purposed for food packaging as well on FDA use in the food handling industry, offering an easier to clean and cleaner surface. In marine and dock applications, blue HDPE sheet is common as blue is visible in the water and is UV stable. Black HDPE sheets are ideal as agricultural liners and outdoors for furniture and playgrounds as they are UV stable and can withstand limited heat. on accuracy within the food handling industry, with a more sanitize-able and cleaner surface. Blue HDPE sheet is typically used in marine and dock applications , as blue can easily be seen in a water environment and is stable to UV light.

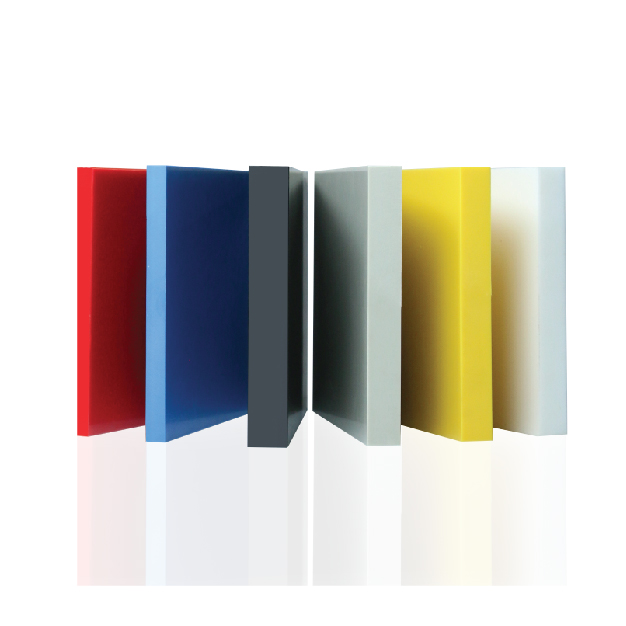

Color Variants and Their Specific Benefits

The color of HDPE sheets often identifies where the product can be used and the performance under certain conditions. HDPE sheets black have carbon black added to them, which makes them UV resistant and able to withstand long-term exposure to outdoor weather conditions. The black sheets are often used in farming, in industrial tanks, and civil constructions. White HDPE sheet, being clean and non-toxic, is also used increasingly in kitchens, laboratories, and areas that must maintain a sanitary surface. This material is also pleasing aesthetically and has a lot of wear resistance. Blue HDPE sheet is often seen used in aquatic and recreational forms, from boat components to water tanks. The color blue also helps with visibility, and improves design, but the strength and durability of the material is unchanged.

Advantages That Make HDPE Sheets Stand Out

There are many compelling reasons that industry prefer White hdpe sheet to other materials such as PVC or wood. HDPE has a very high degree of resistance to corrosive chemicals and does not tend to absorb moisture at all. It gives a great deal of impact resistance which is critical when mechanical or wear-thru pressures are applied on the surface. HDPE is recyclable, which also meets some sustainability goals. In addition, the sheets are fabricated easily using a myriad of methods including machining, welding, and thermoforming during distribution and manufacturing operations. The different sizes and aesthetic choices in black, white and blue sheets allow the industries that use them to conform to its functional needs as well as its design and visual requirements.

HDPE Sheets in Emerging Industries and Innovations

HDPE sheets are being utilized in ways beyond conventional presence and traditional use across new emerging industries. In the renewable sector, HDPE is often not seen as more than a durable UV resistant sheet of material, and in most cases, the backing for solar panels, and for those in the off industry, a reusable build plate in 3D printing and fabrication. The agriculture industry is already incorporating HDPE sheets on vertical farming configurations, flooring solutions in greenhouses, and also in hydroponic systems. The need and demand for lightweight long-life materials are increasing, this has unlocked functional benefits for not only Black HDPE sheet options but colored options as well, which offer design flexibility without changing performance. As the industries shift, HDPE is positioned to play even a more prominent role in delivering enhanced performance opportunities.

Maintenance, Handling, and Environmental Impact

Maintenance is low, so overall costs are low, over the life of the product HDPE sheets have very little upkeep. Cleaning tasks are decreased, and thus, hygiene is improved. When handling sheet products, care must be taken to not create deep scratches or puncture holes. This is predominantly the case in very heavy application, high-stress situations. The second strong, green fact of HDPE is simply that it is 100% recyclable in all states Often commercial products that are recycled are reused in making more HDPE sheets or in manufacturing another plastic product.

Conclusion: A Material Built for the Future

In summary, HDPE sheets have proven to be a mainstay in industrial and commercial settings and residential life From black HDPE sheets in construction and agriculture, to Blue hdpe sheet The many benefits of HDPE sheets include many more than just functional ones—HDPE sheets are environmentally friendly, cost effective, and even customizable in terms of color and look. The advancement of HDPE sheets as industries continue to creatively innovate in both building materials and personal items. When dealing with sheet product, we must be careful not to create deep scratches or points where puncture holes form. This is particularly true in very heavy application, high-strength scenarios. The second strong, green fact of HDPE.

Frequently Asked Questions (FAQ)

1. Who is the largest supplier of HDPE SHEET?

Singhal Industries Private Limited the largest supplier of HDPE SHEET can differ depending on the region you are located in, as well as the market demand. However, there are a few families of companies that control the majority of the global market, by supplying high quality HDPE SHEETS in different thicknesses, colors, and specifications for industrial and commercial purposes.

2. Who is the largest exporter of HDPE SHEET?

When exporting for the global market, countries such as India, China, and the USA have a few of the biggest exporters of HDPE SHEETS. Singhal Industries Private Limited is among Indian exporters and is known for exporting high grade HDPE SHEETS to over 80 developing and developed countries.

3. Who is the largest manufacturer of HDPE SHEET?

Singhal Industries Private Limited is one of the largest manufacturer of HDPE SHEETS in India and also one of the most trusted manufacturers. The company provides HDPE SHEETS in many different colors and dimensions for the domestic and global customers.

4. What is HDPE sheet used for?

HDPE SHEETS use in a number of applications including chemical tanks, water storage, construction, marine structures, industrial packaging, and as lining material for geomembranes because of their resistance to chemicals and longevity.

5. Are HDPE sheets resistant to UV rays?

Yes. HDPE sheets are available in UV-stabilized color options, making them appropriate for outdoor uses as the sheet will hold up with mechanical properties and color for extended exposure to the sun.

6. What colors are available for HDPE sheets?

Generally HDPE sheets are available in black, white, and blue colors. Custom colors are available based on the amount of order and needs for that product within an industrial process.

7. Can HDPE sheets be recycled?

Yes. HDPE sheets are 100% recyclable. They can be melted and reformed into other plastic products. This aspect makes HDPE sheets a great source for many industries for being much more environmentally friendly.

8. Are food-grade HDPE sheets available?

Yes, food-grade HDPE sheets are available and also used across many industries that require hygiene and safety compliance, i.e., food processing, food packaging, and beverage manufacturing.

9. What is the temperature rating of HDPE sheets?

HDPE sheets tend to perform well in temperatures of -50°C to +80°C. Cold and moderate heat is no concern and will not harm the structural integrity of the materials.

10. Why is Singhal Industries Private Limited a trusted name in the manufacturing of HDPE sheets?

Singhal Industries Private Limited is trusted for its high-tech manufacturing plants, solid delivery record, stringent quality control, and strong commitment to customer satisfaction. The HDPE sheets supplied, notably have best practices which adhere to global standards making it a market leader in the sale of HDPE sheet materials across multiple industries.