In the modern world of global trade and complex supply chains, delivering products safely to customers has become a major challenge for manufacturers, suppliers, and logistics companies. Products travel thousands of kilometers, are handled by multiple people, and pass through various storage and transport phases. Despite all efforts, accidental drops remain one of the most common reasons for product damage during handling, shipping, and storage.

Such damage not only results in significant financial losses but also impacts a company’s brand image and customer satisfaction levels. To minimize these risks, businesses need to implement strict quality control measures. One of the most effective and widely adopted methods for testing packaging and product durability is Drop Testing, and Pacorr’s Drop Tester for Packaging and Product Safety is the ideal solution.

What is a Drop Tester?

A Drop Tester is a specialized laboratory instrument used to evaluate the ability of products and packaging to withstand accidental drops and impacts. It simulates real-world scenarios where a product or packaged item may be dropped from a specific height, replicating the forces experienced during shipping, handling, or storage.

Drop testing allows manufacturers to assess the protective qualities of their packaging, identify potential weaknesses, and make necessary improvements before products enter the market. This not only enhances product safety but also ensures compliance with global standards and regulations.

Why is Drop Testing Essential?

No matter how careful people are, accidental drops are inevitable during a product’s journey from factory to customer. Products may be dropped during warehouse handling, transportation loading or unloading, or even by consumers themselves. If packaging is not strong enough to absorb the shock, it can lead to:

-

Product breakage or malfunction

-

Financial losses from product replacements

-

Increased returns and customer complaints

-

Damaged brand reputation

-

Higher logistical costs

Drop Testing helps eliminate these risks by:

✔ Evaluating product and packaging durability

✔ Identifying structural weaknesses in packaging design

✔ Ensuring products can withstand real-world handling conditions

✔ Improving packaging materials for optimal protection

✔ Reducing product damage and loss during transit

✔ Ensuring compliance with international quality standards such as ASTM D5276 and ISO 2248

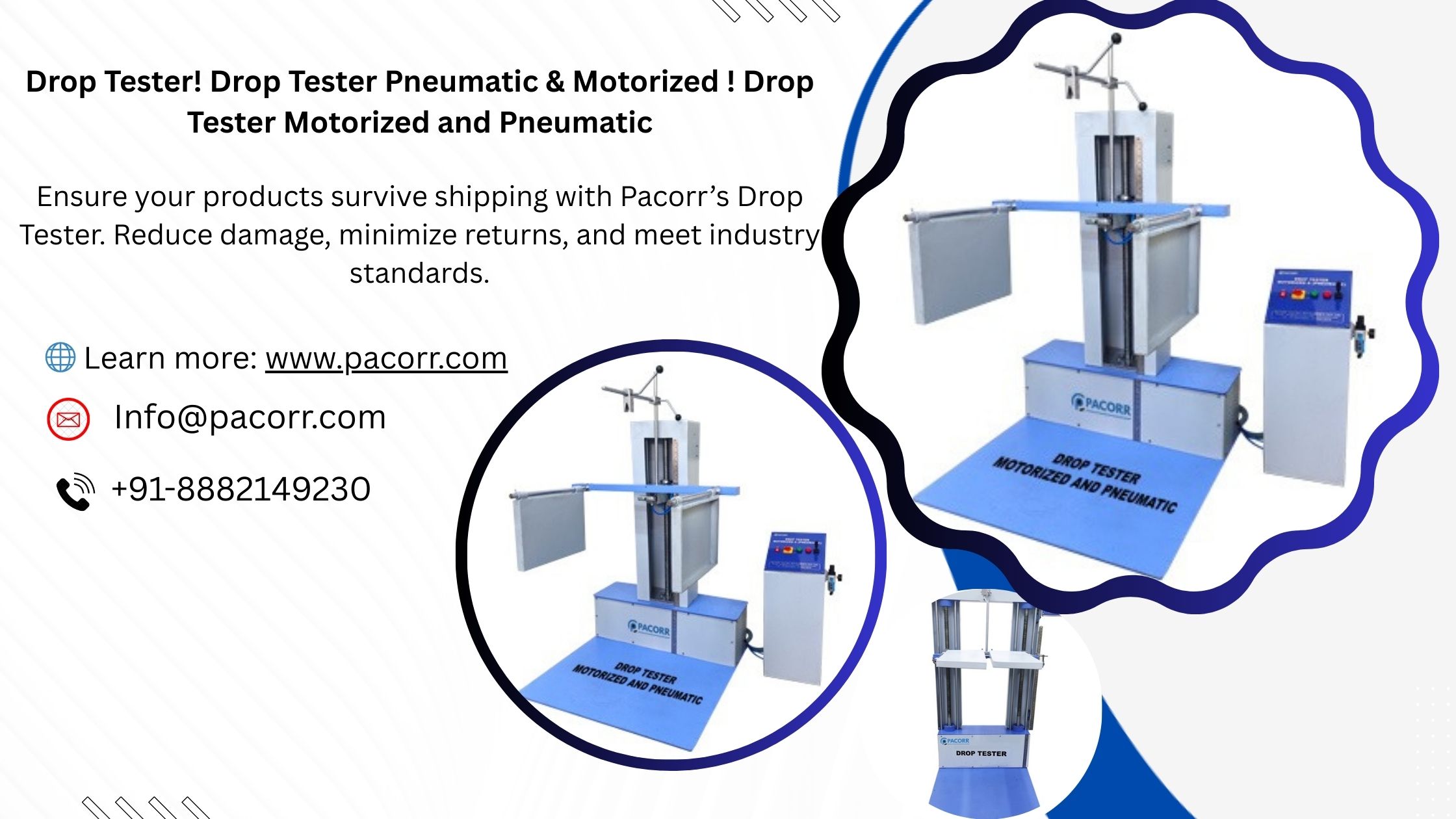

Pacorr’s Drop Tester: Designed for Precision and Reliability

At Pacorr, we understand that product and packaging safety is critical to business success. That’s why we have developed high-quality Drop Testers that deliver precise, reliable, and repeatable results.

Our Drop Testers are engineered to simulate various drop scenarios, allowing manufacturers to thoroughly test their products and packaging under controlled laboratory conditions. Whether it’s a small consumer product or a large industrial component, our Drop Testers can handle a wide range of items for accurate durability assessment.

Key Features of Pacorr’s Drop Tester:

✔ Adjustable Drop Height: Simulate drops from different heights to replicate real-world conditions.

✔ Flat, Edge, and Corner Drop Testing: Assess protection from all potential impact points.

✔ Sturdy, Durable Construction: Built to withstand repeated use and provide stable, consistent results.

✔ User-Friendly Operation: Easy sample placement and intuitive controls for hassle-free testing.

✔ Compliant with Global Standards: Meets recognized standards like ASTM D5276 and ISO 2248 for accurate, reliable testing.

✔ Wide Testing Application: Suitable for boxes, cartons, bottles, containers, electronics, consumer goods, and industrial products.

How Drop Testing Works

The Drop Testing process is designed to be simple, effective, and comprehensive:

-

Specimen Placement: The product or packaged item is securely placed on the drop platform.

-

Height Adjustment: The desired drop height is set based on real-world handling scenarios or regulatory requirements.

-

Drop Simulation: The product is released, allowing it to fall freely onto a hard surface to simulate accidental drops.

-

Impact Inspection: The product and packaging are examined for visible damage, deformation, or compromised functionality.

-

Repeat Testing: Multiple drops are performed from different orientations (flat, edge, corner) to evaluate protection comprehensively.

-

Result Analysis: Test results help manufacturers assess packaging effectiveness and make necessary improvements.

Industries That Rely on Pacorr’s Drop Tester

Drop Testing is a critical part of the quality control process for industries where packaging and product safety are essential, including:

1. Packaging and Logistics

Packaging manufacturers and logistics companies use Drop Testers to ensure that boxes, cartons, and protective materials can withstand accidental drops and impacts during transportation.

2. Electronics and Appliances

Fragile electronic devices require robust packaging. Drop Testing ensures the packaging protects sensitive components from damage during shipping and handling.

3. E-commerce and Retail

With online shopping booming, products often travel individually to consumers. Drop Tester Price confirms that packaging provides sufficient protection for safe last-mile delivery.

4. FMCG (Fast-Moving Consumer Goods)

Bottled, canned, and packaged goods must survive accidental drops to prevent spillage, contamination, or breakage. Drop Testing validates packaging integrity.

5. Pharmaceuticals and Healthcare

Medical devices and pharmaceutical products require high packaging standards to maintain safety. Drop Testing ensures packaging protects contents from impact-related damage.

6. Automotive Components

Heavy and delicate automotive parts need durable packaging. Drop Testing guarantees components reach assembly lines undamaged.

Benefits of Using Pacorr’s Drop Tester for Packaging and Product Safety

By choosing Pacorr’s Drop Tester, businesses can:

✅ Reduce product damage and financial losses

✅ Improve packaging design and material efficiency

✅ Minimize returns, replacements, and customer complaints

✅ Enhance product and packaging safety

✅ Meet global regulatory standards

✅ Boost brand reputation and customer satisfaction

Conclusion

In a world where product damage can result in significant losses and brand damage, Drop Testing is no longer optional — it’s a necessity. With Pacorr’s Drop Tester for Packaging and Product Safety, manufacturers can confidently assess packaging strength, identify design flaws, and deliver products that are well-protected from the risks of accidental drops.

By investing in reliable drop testing equipment, businesses can reduce damage-related costs, enhance product durability, and build long-term customer trust.