In the realm of artificial heating, ventilation, air conditioning, and process cooling systems, maintaining peak effectiveness isn’t just a matter of functional convenience but a critical factor in energy operation and cost control. Coil replacements represent one of the most poignant conservation interventions available to installation directors and masterminds seeking to restore or enhance the performance of their thermal operation systems. Whether dealing with eroded tubes, fouled shells, or simply outdated coil designs that no longer meet ultramodern effectiveness norms, understanding when and how to execute coil reserves can mean the difference between a system that drains coffers and one that operates at optimal performance situations. This comprehensive companion explores the strategic considerations, benefits, and stylish practices associated with heat exchanger coil relief systems.

Feting the Signs That Coil relief Is Necessary

Before embarking on a coil relief design, it’s essential to directly diagnose the condition of being heat exchanger coils and determine whether relief truly offers the stylish return on investment compared to form or drawing druthers. Several reflective pointers suggest that relief rather than recuperation is the applicable course of action.

Visible erosion that has progressed beyond face oxidation frequently signals structural concession that cleaning can not remedy. When erosion has created pitting or perforation in the coil tubes, the integrity of the pressure boundary is compromised, and leaks come ineluctable. also, mechanical damage from impacts, indurate events, or inordinate vibration may have misshaped fins or damaged tube walls in ways that can not be adequately repaired.

Performance declination provides another critical index. When a heat exchanger constantly fails to achieve its design temperature differentials despite thorough cleaning and proper tailwind or water inflow, the coil itself may have degraded internally. Scale buildup inside tubes, corrosion of internal shells, or loss of fin- to- tube contact due to repeated thermal cycling can all dwindle heat transfer capacity to the point where relief becomes further provident than uninterrupted operation.

Age and technological fustiness also factor into relief opinions. Coils designed and manufactured decades agone frequently employed accoutrements, fin consistence, and tube configurations that are sour by current norms. Replacing these heritage coils with ultramodern designs can deliver dramatic advancements in effectiveness, indeed when the old coils are still technically functional.

Opting the Right relief Coil Design

The relief coil selection process requires careful consideration of multiple factors to insure optimal performance in the specific operation. This is n’t simply a matter of ordering a coil with matching confines to the original unit.

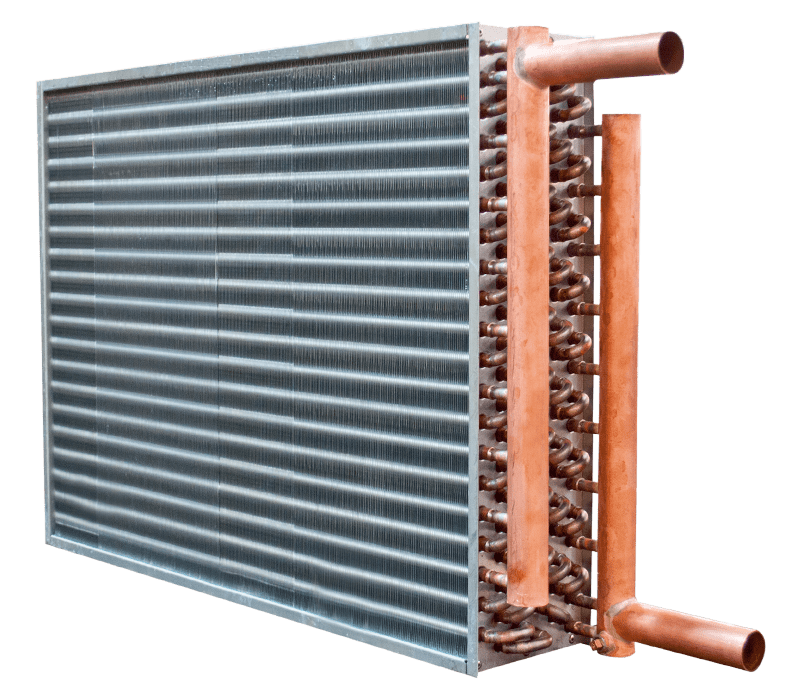

Material selection stands as the first critical decision. Bobby tubes with aluminum fins remain the most common and cost-effective choice for standard HVAC operations, offering excellent thermal conductivity and proven trustability. still, littoral surroundings or operations involving sharp atmospheres may justify the fresh investment in carpeted bobby, cupronickel blends, or indeed pristine sword construction to extend service life and reduce the frequence of unborn reserves.

Fin configuration significantly impacts both heat transfer effectiveness and pressure drop characteristics. ultramodern relief coils frequently feature enhanced fin designs similar as louvered, crimpy, or shaft- and- neutralize patterns that produce salutary turbulence and ameliorate heat transfer portions compared to plain flat fins. adding fin viscosity, measured in fins per inch, can boost heat transfer face area, but this must be balanced against the increased air- side pressure drop and lesser vulnerability to fouling in dirty surroundings.

Circuitry design determines how the heat transfer fluid is routed through the coil and directly affects capacity, pressure drop, and temperature uniformity. Multi-pass circuits with counterflow arrangements generally give superior thermal performance compared to simple parallel inflow designs. Working with educated thermal masterminds during the design phase ensures that the relief coil’s circuitry is optimized for the factual operating conditions rather than simply replicating an outdated original design.

Installation Stylish Practices for Maximum Longevity

Indeed the loftiest quality relief coil will underperform if installation procedures are shy. Proper installation practices cover the investment and insure that the new coil delivers its full performance implicit throughout its design life.

Pre-installation examination of the outfit casing or air running unit is essential. Before removing the old coil, corroborate that the drain visage is complete and duly leaned, that mounting rails or supports are structurally sound, and that there are no obstructions or damage to the girding press. Addressing these ancillary issues during the relief design prevents unseasonable declination of the new coil.

The junking of the old coil must be executed with care to avoid damaging the girding structure. Refrigerant or water circuits must be duly insulated, vacated, and purified according to applicable canons and environmental regulations. Any remaining fluids should be captured and disposed of responsibly.

When situating the new coil, icing proper alignment and secure underpinning prevents vibration and stress that could lead to unseasonable failure. All connection points for refrigerant lines, water pipeline, or condensate rainspouts must be executed with applicable accoutrements and ways. Brazed connections should be performed with proper heat control and inert gas purging to help oxidation inside the tubes. Threaded or flanged connections bear proper gaskets, sealants, and necklace specifications.

System commissioning following coil installation verifies that the relief has been successful. This includes pressure testing for leaks, flow testing to confirm proper water or refrigerant distribution, and performance verification through temperature and capacity measures. Comprehensive attestation of birth performance provides precious reference data for unborn conservation opinions.

Preventative Measures to Extend relief Coil Life

Once a new coil has been installed, enforcing a robust preventative conservation program maximizes the return on investment by extending the service life of the relief unit. Several strategies have proven effective across colorful operations.

Regular cleaning of both air- side and water- side shells prevents the accumulation of fouling accoutrements that reduce heat transfer effectiveness and accelerate erosion. Air- side cleaning should do at intervals applicable to the terrain, with advanced frequentness needed in fine or artificial settings. Water- side cleaning and chemical treatment programs maintain heat transfer shells while controlling scale, erosion, and natural growth.

Water treatment protocols are particularly critical for coils in unrestricted- circle or open- circle water systems. Proper pH control, erosion impediments, and scale preventers cover tube internals from the chemical and electrochemical processes that beget unseasonable failure. In open systems, filtration and regular blowdown reduce the attention of dissolved solids and suspended patches.

Vibration monitoring and insulation cover coils from mechanical stress. duly designed and maintained mounting systems, along with flexible connections at pipeline interfaces, minimize the transmission of vibration from pumps, suckers, or external sources that can fatigue tube accoutrements and loosen fin-to-tube bonds.

Partnering with Endured Heat Exchanger Specialists

Successfully executing a coil relief design requires further than just copying the right outfit; it demands access to specialized moxie, quality factors, and dependable support throughout the process. Partnering with established specialists in thermal operation results ensures that every aspect of your relief design is handled with the professionalism and perfection it deserves. For those seeking comprehensive support for heat exchanger coil relief systems, including engineering discussion, custom coil design, and specialized coffers, exploring the results available at Kinetic Engineering provides access to the moxie and products demanded to restore and optimize system performance effectively.

Conclusion

Coil relief systems represent significant openings to enhance system effectiveness, reduce energy consumption, and extend outfit service life in heating, cooling, and process operations. By feting when relief is necessary, opting meetly designed coils for specific operating conditions, executing installation with scrupulous attention to detail, and enforcing preventative conservation protocols, installation directors can insure that their thermal operation systems deliver dependable, effective performance for times to come. As energy costs continue to rise and sustainability becomes decreasingly important, the strategic relief of underperforming heat exchanger coils stands as one of the most cost-effective interventions available. Whether addressing exigency failures or proactively upgrading growing outfit, approaching coil relief with proper planning and prosecution transforms a conservation necessity into a performance improvement occasion that delivers palpable benefits across functional, fiscal, and environmental confines.