Explore high-performance CNC tools built for precision machining, durability, and consistent results across milling, turning, and drilling applications.

High-Quality CNC Tools for Precision Machining Applications.

Precision machining is the backbone of modern manufacturing industries, ranging from automotive and aerospace to medical devices and electronics. At the heart of this precision lies the quality of CNC tools. High-quality CNC tools ensure dimensional accuracy, superior surface finishes, and consistent performance across high-volume production. As machining demands become more complex, manufacturers increasingly rely on advanced CNC machine tools that deliver reliability, efficiency, and long tool life.

Importance of Precision in CNC Machining1

Precision machining involves producing components with extremely tight tolerances and minimal deviation from design specifications. Even the smallest error can affect functionality, safety, or assembly compatibility. High-quality CNC tools play a critical role in maintaining this precision by offering stable cutting performance, reduced vibration, and excellent wear resistance. The right CNC tool selection directly impacts productivity, cost efficiency, and final product quality.

Understanding CNC Machine Tools

A CNC machine tool is a computer-controlled device used to remove material from a workpiece with high accuracy. These tools follow programmed instructions to perform operations such as milling, turning, drilling, boring, and threading. Modern CNC machine tools combine mechanical strength with digital intelligence, enabling manufacturers to produce complex geometries with consistent results. The quality of these tools determines the overall efficiency of the machining process.

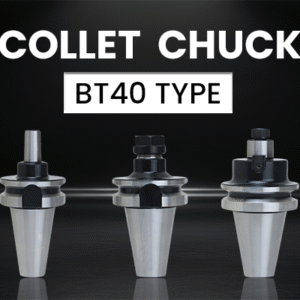

Types of CNC Tools Used in Precision Machining

Precision machining applications require a wide variety of CNC tools, each designed for specific operations. Common tools include end mills, drill bits, turning inserts, boring bars, face mills, and threading tools. Specialized tools such as micro end mills and CNC tool and mill 3mm cutters are widely used for detailed machining where fine features and tight tolerances are essential. Selecting the right tool geometry and material is crucial for achieving optimal performance.

Role of Tool Material in Machining Accuracy

The material used in CNC tools significantly affects cutting performance and tool life. Carbide tools are widely preferred due to their high hardness, heat resistance, and ability to maintain sharp cutting edges. Coated carbide tools further enhance wear resistance and reduce friction. High-speed steel tools are still used in certain applications, but advanced carbide CNC machine tools dominate precision machining environments where speed and accuracy are critical.

CNC Tool and Mill 3mm for Fine Machining

CNC tool and mill 3mm cutters are essential for intricate machining tasks such as mold making, die manufacturing, and precision component production. These small-diameter tools enable machinists to achieve detailed contours, narrow slots, and fine surface finishes. High-quality 3mm end mills are engineered to minimize deflection, reduce chatter, and maintain cutting accuracy even at high spindle speeds.

Benefits of Using High-Quality CNC Tools

Investing in high-quality CNC tools offers multiple benefits for manufacturers. These tools provide consistent cutting performance, longer tool life, and reduced downtime due to fewer tool changes. Improved surface finishes minimize secondary operations, saving both time and cost. Additionally, premium CNC machine tools enhance process stability, ensuring repeatable results across multiple production cycles.

CNC Machine Tool Manufacturer Standards and Innovation

Choosing the right CNC machine tool manufacturer is crucial for achieving precision machining success. Leading manufacturers adhere to strict quality standards, advanced manufacturing processes, and continuous innovation. Precision grinding, rigorous quality inspections, and advanced coatings ensure that CNC tools meet the demanding requirements of modern industries. A reliable manufacturer focuses not only on tool performance but also on customer support and application expertise.

CNC Machine Tool Online Availability and Convenience

The digital transformation of the manufacturing industry has made CNC machine tools online purchasing more accessible than ever. Online platforms allow customers to browse a wide range of CNC tools, compare specifications, and select products tailored to their machining needs. Buying CNC machine tools online saves time, increases transparency, and provides access to detailed product information, technical support, and fast delivery options.

Tool Geometry and Its Impact on Machining Performance

Tool geometry plays a vital role in determining cutting efficiency and surface quality. Factors such as rake angle, helix angle, flute design, and edge preparation influence chip evacuation and cutting forces. High-quality CNC tools are designed with optimized geometries to reduce heat generation, improve chip flow, and enhance tool stability. This results in smoother machining operations and extended tool life.

Applications of CNC Tools Across Industries

CNC tools are widely used across multiple industries that demand precision and consistency. In the automotive sector, they are used for engine components, transmission parts, and braking systems. Aerospace applications rely on CNC tools for machining complex components from high-strength alloys. Medical device manufacturing requires ultra-precise CNC machine tools for implants and surgical instruments, while electronics industries use micro tools for detailed component fabrication.

Maintenance and Care of CNC Machine Tools

Proper maintenance is essential to preserve the performance of CNC machine tools. Regular inspection, correct tool storage, and appropriate cutting parameters help extend tool life. Using the right coolant and lubrication reduces heat buildup and prevents premature wear. High-quality CNC tools are designed to withstand demanding conditions, but proper care ensures consistent precision and long-term reliability.

Enhancing Productivity with Advanced CNC Tooling

Advanced CNC tooling solutions help manufacturers improve productivity without compromising quality. High-performance coatings, optimized tool paths, and application-specific designs enable faster cutting speeds and higher feed rates. When combined with reliable CNC machine tools, these advanced solutions reduce cycle times and increase overall machining efficiency, making them ideal for both small workshops and large-scale production facilities.

Sustainability and Efficiency in Modern Machining

Modern manufacturing emphasises sustainability and resource efficiency. High-quality CNC tools contribute to this goal by reducing material waste, minimizing tool consumption, and lowering energy usage. Longer tool life and consistent performance lead to fewer replacements and less downtime, supporting environmentally responsible machining practices while maintaining high production standards.

Why Choose Jaibros for CNC Tools

Jaibros stands out as a trusted CNC machine tool manufacturer committed to delivering precision, durability, and performance. With a comprehensive range of CNC tools designed for milling, turning, drilling, and specialized machining, Jaibros meets the diverse needs of modern manufacturers. The company focuses on quality-driven manufacturing, rigorous testing, and customer-centric solutions to ensure every CNC machine tool delivers consistent and reliable results. Jaibros also offers CNC machine tool online accessibility, making it easy for customers to find and purchase the right tools for their applications.

Conclusion

High-quality CNC tools are essential for achieving precision machining excellence in today’s competitive manufacturing landscape. From CNC tool and mill 3mm cutters to advanced carbon solutions, the right tools ensure accuracy, efficiency, and long-term cost savings. Selecting reliable CNC machine tools from a trusted CNC machine tool manufacturer, like Jaibros, enables manufacturers to meet demanding production requirements with confidence. By investing in premium CNC tooling and embracing modern machining practices, businesses can enhance productivity, improve product quality, and stay ahead in an evolving industrial environment.