In today’s manufacturing world, precision, durability, and customization are paramount. Industries ranging from automotive to construction rely heavily on metal components crafted through the sheet metal fabrication process. This versatile process enables the transformation of flat metal sheets into various parts and structures. When combined with advanced techniques like CNC bending services in Pune, it becomes a powerhouse of efficiency and accuracy.

If you’re seeking a trusted partner for high-quality fabrication, understanding the key steps and technologies involved will help you make informed decisions. Let’s dive into the intricacies of the sheet metal fabrication process and explore how CNC bending services enhance its scope.

What is the Sheet Metal Fabrication Process?

The sheet metal fabrication process is a series of steps used to convert flat metal sheets into functional products or parts. The process involves cutting, bending, assembling, and finishing to achieve the final form. It is widely used in industries such as:

- Automotive manufacturing

- Aerospace and aviation

- Electrical and electronics

- Construction and infrastructure

- Home appliances and furniture

The primary goal is to create durable, precise, and aesthetically pleasing components that meet specific design and functional criteria.

Key Steps in the Sheet Metal Fabrication Process

- Design and Engineering

Everything starts with a design. Engineers create detailed CAD (Computer-Aided Design) models that serve as blueprints for the fabrication. These designs determine dimensions, tolerances, and material specifications.

- Material Selection

Choosing the right metal is crucial. Common materials include:

- Stainless Steel

- Aluminum

- Carbon Steel

- Copper

- Brass

Each material has its own properties suited for different industrial requirements like corrosion resistance, strength, and malleability.

- Cutting

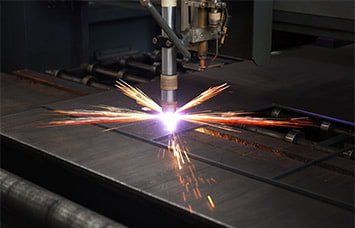

Laser cutting, plasma cutting, and waterjet cutting are commonly used to trim the sheet metal into desired shapes. Among these, laser cutting offers high precision and is ideal for intricate designs.

- Bending

This is where CNC bending services in Pune come into play. CNC (Computer Numerical Control) bending machines automate the process of forming angles and curves in metal sheets. This ensures consistent results, especially in large-scale productions.

- Punching and Forming

Punching involves creating holes or shapes using specialized tools. Forming further shapes the metal into complex profiles.

- Welding and Assembly

Once parts are shaped, they are welded or fastened together. Precision welding techniques like TIG and MIG welding are used depending on the material and application.

- Finishing

The final touch includes powder coating, painting, deburring, and polishing to improve aesthetics and prevent corrosion. This stage is essential for parts that will be exposed to the elements.

The Role of CNC Bending in Sheet Metal Fabrication

CNC bending services in Pune have revolutionized the sheet metal industry by providing unmatched accuracy and repeatability. Here’s why CNC bending is essential:

- Precision: CNC machines operate with exact specifications, reducing errors.

- Speed: Automation significantly decreases processing time.

- Flexibility: Accommodates various materials and thicknesses.

- Consistency: Every part is identical, making it ideal for mass production.

CNC bending is particularly beneficial when dealing with complex designs or when high-volume production is required. It minimizes human error and ensures high-quality output every time.

Why Choose CNC Bending Services in Pune?

Pune has emerged as a manufacturing hub in India, known for its advanced engineering and skilled workforce. Opting for CNC bending services Pune comes with several advantages:

- Technological Edge: Most facilities are equipped with the latest CNC machines.

- Cost-Efficiency: Competitive pricing without compromising quality.

- Quick Turnaround: Faster delivery timelines due to proximity and local expertise.

- Customization: Tailored solutions to meet your specific fabrication needs.

Samarth Sharp Edge is one of the reputed names offering reliable CNC bending and sheet metal fabrication solutions in Pune. Their commitment to quality, precision, and customer satisfaction makes them a preferred partner for industries across the board.

Applications of Sheet Metal Fabrication with CNC Bending

The combination of sheet metal fabrication process and CNC bending opens doors to endless possibilities. Some common applications include:

- Control panels and enclosures

- Automotive chassis and body parts

- HVAC components

- Architectural elements like railings and frames

- Electrical cabinets and machine parts

Whether it’s a prototype or a full-scale production, sheet metal fabrication ensures durability and performance in every application.

Factors to Consider While Choosing a Sheet Metal Fabrication Partner

- Experience and Expertise: Look for companies with a proven track record in metal fabrication and CNC operations.

- Technology Stack: Ensure they use modern equipment like CNC press brakes and automated cutting machines.

- Material Versatility: A good fabricator should offer solutions in a wide range of metals.

- Quality Assurance: Certifications, inspection protocols, and consistency in delivery indicate a reliable partner.

- Customization Capability: Your partner should be able to accommodate custom projects, including one-off pieces and batch productions.

Samarth Sharp Edge ticks all these boxes, offering high-end solutions tailored to your industry needs.

Future of Sheet Metal Fabrication and CNC Bending

With the rise of Industry 4.0, the sheet metal fabrication process is rapidly evolving. Integration of IoT-enabled machines, robotics, and AI is enabling even more precise and intelligent fabrication systems. CNC bending, in particular, will continue to play a crucial role in reducing manual intervention and improving throughput.

Businesses that leverage these technologies can reduce lead times, cut costs, and maintain superior product quality—giving them a competitive edge.

Conclusion

The sheet metal fabrication process is an essential aspect of modern manufacturing. When combined with CNC bending services in Pune, it offers unmatched precision, speed, and reliability. From design to finishing, every stage plays a critical role in delivering high-quality metal components.

For businesses looking to streamline their fabrication needs, partnering with an expert like Samarth Sharp Edge ensures efficiency, customization, and long-term value. Whether you’re creating industrial equipment, automotive parts, or custom metal structures, embracing the power of CNC technology can redefine the way you build and innovate.