Antibody discovery often begins with small-scale expression, producing just enough material for early screening and proof-of-concept studies. At this stage, milligram quantities may be sufficient to confirm target binding or basic functionality. However, once an antibody demonstrates promise, the requirements change rapidly. Preclinical studies, assay development, comparative testing, and translational research demand significantly larger quantities of highly consistent material.

This transition from exploratory work to sustained research is where large scale antibody production becomes essential. Scaling antibody manufacturing is not simply about increasing volume. It is about maintaining molecular integrity, reproducibility, and functional performance as production expands. Without a robust large-scale strategy, even strong antibody candidates can stall due to supply limitations or batch variability.

What Is Large Scale Antibody Production?

Large scale antibody production refers to the controlled manufacture of antibodies at quantities that exceed discovery-stage expression, often ranging from gram to multi-gram levels. Unlike small-scale laboratory expression, large-scale production emphasises process control, consistency, and quality assurance.

Most large-scale antibody production relies on mammalian expression systems, particularly CHO or HEK-derived cell lines. These systems are preferred because they support:

- Correct antibody folding and assembly

- Human-compatible post-translational modification

- Stable expression over extended culture durations

- Predictable product quality across batches

A typical large-scale production workflow includes:

- Cell line selection or development

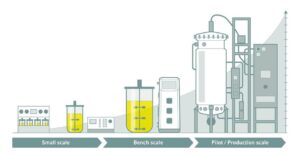

High-producing clones are identified to ensure stable expression and long-term productivity. - Process scale-up

Production transitions from shake flasks to larger culture systems, eventually reaching bioreactors designed for controlled growth and feeding. - Culture optimisation

Media composition, feeding strategies, and environmental parameters are optimised to balance yield and product quality. - Purification and polishing

Multi-step purification removes host cell proteins, aggregates, and contaminants while preserving antibody integrity. - Analytical characterisation

Identity, purity, and functional activity are confirmed to ensure batch consistency.

Manufacturing frameworks discussed by the National Institutes of Health emphasise that maintaining product consistency during scale-up is just as important as achieving higher yields, particularly for biologics intended for downstream development.

Why Scaling Antibody Production Changes Project Outcomes

Consistency Across Extended Research Timelines

Small-scale expression often results in batch-to-batch variability. When studies span months or years, inconsistencies in antibody material can complicate data interpretation. Large scale antibody production enables generation of uniform batches that support long-term experimental continuity.

Support for Translational Studies

Preclinical research frequently requires large quantities of antibody material for pharmacokinetic studies, biodistribution analysis, and toxicology testing. Reviews in Nature Reviews Drug Discovery highlight manufacturing readiness as a critical factor influencing how efficiently antibody programs advance beyond discovery.

Reduced Technical Risk

Establishing scalable production early helps identify manufacturing challenges before they become project bottlenecks. Issues related to stability, aggregation, or expression efficiency are easier to address before timelines become constrained.

Applications of Large Scale Antibody Production

Preclinical and Translational Research

In vivo studies often require repeated dosing across multiple cohorts. Gram-level antibody quantities are needed to ensure consistent material throughout study phases. Large-scale production prevents interruptions caused by re-expression or reformulation.

Diagnostic and Assay Development

Antibodies used in diagnostic assays must perform consistently across multiple production lots. Large scale antibody production supports lot-to-lot reproducibility, which is essential for assay validation and long-term use.

Immuno-Oncology and Targeted Therapies

Cancer therapies increasingly rely on antibody-based approaches, including immune checkpoint inhibitors and antibody combinations. Publications in Nature Biotechnology note that scalable manufacturing is fundamental to evaluating these complex therapeutic strategies reliably.

Biosimilar and Comparative Studies

Comparative studies require consistent antibody material to support analytical similarity testing. Large-scale production enables controlled comparisons across batches and conditions.

Infectious Disease Research

Rapid access to antibody material can be critical during outbreak or response-driven research. Scalable production strengthens preparedness by ensuring sufficient material is available for testing and validation.

Key Challenges in Large Scale Antibody Production

Scaling antibody production introduces technical challenges that must be addressed carefully.

Process Scalability

Conditions that perform well at small scale may behave differently in bioreactors. Changes in oxygen transfer, nutrient gradients, and shear stress can affect expression and product quality.

Product Heterogeneity

Antibody glycosylation and aggregation must be tightly controlled. Even small variations can influence binding, stability, or downstream performance.

Balancing Yield and Quality

Maximising output without compromising molecular integrity requires careful optimisation. Overexpression can sometimes increase misfolding or aggregation.

A discussion in Nature Methods highlights the importance of incremental scale-up, in-process monitoring, and robust analytics to mitigate these risks.

Manufacturing Considerations That Support Success

Early Process Development

Establishing scalable processes early reduces the likelihood of redesign later in development.

Analytical Integration

Regular analytical assessment during production helps detect subtle changes in product quality before they impact studies.

Documentation and Traceability

Even for non-clinical research, well-documented production supports reproducibility and future development planning.

Why Large Scale Antibody Production Matters for the Future

As antibody formats diversify, manufacturing requirements are becoming more complex.

Emerging trends include:

-

Support for engineered formats such as bispecific antibodies and Fc-modified variants

-

Increased emphasis on critical quality attributes

-

Alignment between research-scale and development-scale processes

-

Integration of automation and advanced analytics

These developments help ensure that antibodies generated for research remain suitable for downstream applications without extensive re-engineering.

Benefits Across Research, Industry, and Healthcare

For Researchers

Reliable antibody supply improves experimental consistency and supports long-term studies.

For Biotech and Pharmaceutical Teams

Early scalable production reduces development risk and shortens project timelines.

For Clinicians and Patients

Stable manufacturing pipelines support continuity in translational and therapeutic research.

For Healthcare Systems

Scalable biologic production strengthens readiness for complex and emerging disease challenges.

Conclusion

Large scale antibody production is a foundational capability that enables antibody programs to progress beyond early discovery into sustained research and translational application. By ensuring consistent quality, reliable supply, and controlled manufacturing, large-scale production supports every stage of antibody development that follows initial identification. As antibody-based technologies continue to expand in scope and complexity, large scale antibody production will remain a critical pillar of modern biomedical research.