Introduction: What Exactly Are Aluminium Sheets?

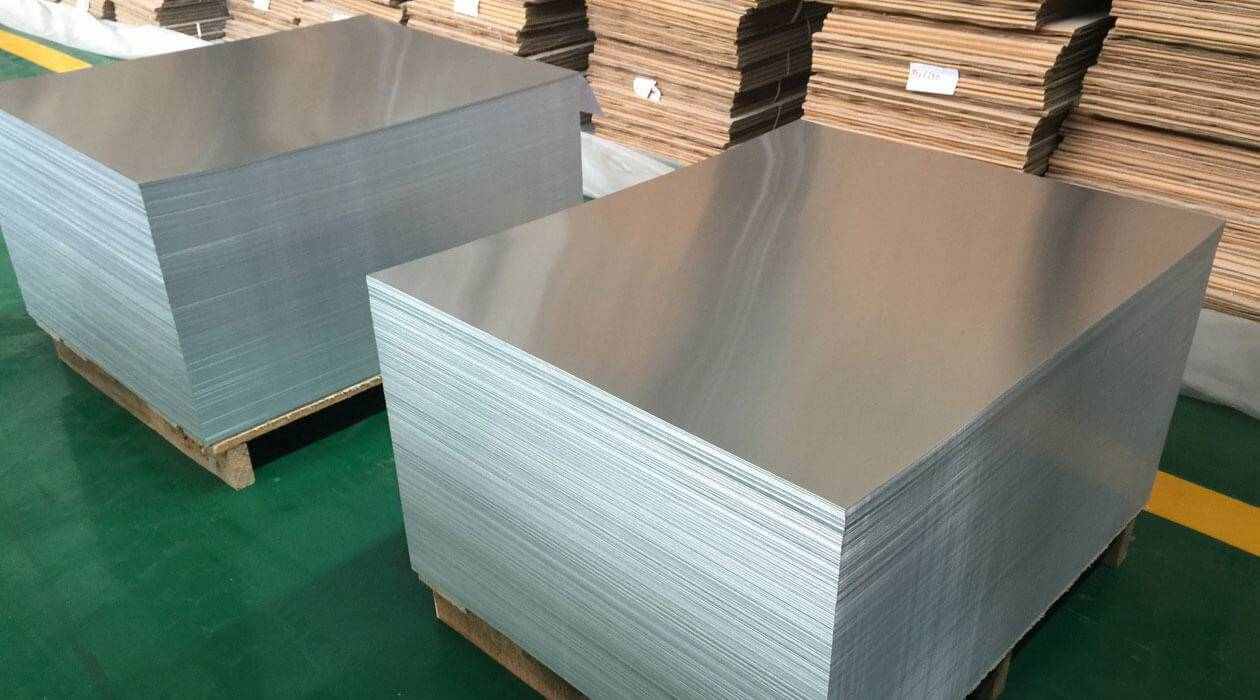

Aluminium sheets are one of the most widely used forms of aluminium. They are thin, flat pieces of metal that can be cut, bent, shaped, or coated to serve different purposes. Because aluminium is lightweight, resistant to corrosion, and strong enough for demanding applications, aluminium sheets have become essential in industries like construction, aerospace, automotive, packaging, and even interior design.

When you look around in daily life, you will notice aluminium sheets almost everywhere—roofing panels, kitchen utensils, car body parts, and even food packaging. Their popularity comes from a unique combination of strength, flexibility, and cost-effectiveness. But to understand why aluminium sheets are so important, let’s look at how they are made, the types available, and the different grades that industries prefer.

How Aluminium Sheets Are Made

The production of aluminium sheets starts with the extraction of aluminium from bauxite ore. Once refined into pure aluminium, the metal is melted and cast into slabs. These slabs are passed through heavy rolling mills that press them into thin, flat sheets of uniform thickness.

Depending on the requirement, these sheets may undergo further treatments such as anodising, coating, or perforation. These treatments improve their durability, strength, or appearance. The end result is a versatile product that can be supplied in different thicknesses, widths, and lengths, depending on customer needs.

The rolling process gives the sheet a smooth surface, while further processing ensures that it meets the required specifications for industries such as construction, marine, or aerospace.

Types of Aluminium Sheets

Not all aluminium sheets are the same. Different types are made to suit specific applications. Here are the most common varieties:

-

Plain Aluminium Sheets – These are the standard, flat sheets commonly used for roofing, wall cladding, siding, and general construction purposes. They are also used in manufacturing utensils and packaging materials.

-

Chequered Aluminium Sheets – Recognisable by their raised patterns, chequered sheets are used in flooring, staircases, and industrial walkways because the textured design prevents slipping. They are also common in transport vehicles and storage areas.

-

Anodised Aluminium Sheets – These sheets undergo an anodising process, which makes the surface more resistant to corrosion and wear. Anodising also gives the sheet an attractive finish, making it popular in architectural and decorative applications.

-

Perforated Aluminium Sheets – Sheets with punched holes, often used for filtration, ventilation, acoustic panels, and decorative facades. They also find use in modern architectural projects where both design and functionality matter.

-

Coated Aluminium Sheets – These sheets are covered with protective or decorative coatings, such as paint or polymer films, to improve their appearance and resistance to harsh environments.

Each type of sheet has its own role, and choosing the right one depends on the project’s requirements.

Grades of Aluminium Sheets

Aluminium sheets are produced in several grades, each with different mechanical and chemical properties. Here are some of the most common:

-

1100 Grade – This is commercially pure aluminium. It is soft, lightweight, and highly resistant to corrosion. It is commonly used in roofing, siding, utensils, and chemical equipment.

-

3003 Grade – A popular alloy with manganese, known for its excellent corrosion resistance and strength. It is often used in roofing sheets, siding, storage tanks, and fuel tanks.

-

5052 Grade – This grade offers high strength and excellent resistance to marine environments, making it ideal for shipbuilding, automotive parts, and pressure vessels.

-

6061 Grade – A versatile alloy with good strength, corrosion resistance, and weldability. It is widely used in aerospace, automotive frames, and structural components.

-

7075 Grade – Known for its exceptional strength, this grade is used in aerospace, defence, and high-performance applications where durability is critical.

By selecting the right grade, industries can ensure that the aluminium sheet performs well in its intended environment.

Common Uses of Aluminium Sheets

Aluminium sheets have countless uses across multiple industries. Some of the most common applications include:

-

Construction – Roofing, cladding, wall panels, false ceilings, and insulation are all made from aluminium sheets. Their lightweight nature makes them easy to install, while their corrosion resistance ensures long-term durability.

-

Automotive – Car body panels, hoods, engine parts, and structural components are often manufactured from aluminium sheets. Using aluminium helps reduce vehicle weight, improving fuel efficiency and performance.

-

Aerospace – Aluminium sheets are crucial in aircraft manufacturing, where lightweight yet strong materials are required. From wings to fuselage panels, aluminium plays a central role in reducing weight while maintaining strength.

-

Packaging – Aluminium sheets and foils are used to make beverage cans, food containers, and packaging foils. Aluminium is safe, recyclable, and provides an effective barrier against moisture and light.

-

Marine Industry – Because of their excellent resistance to saltwater corrosion, certain aluminium sheet grades are used in shipbuilding, boat panels, and offshore structures.

-

Household and Decorative Items – From kitchen utensils to interior décor, signage, and furniture, aluminium sheets are part of everyday life.

Why Aluminium Sheets Are Popular

There are several reasons why aluminium sheets are preferred over other materials:

-

Lightweight yet strong – Aluminium provides excellent strength without adding unnecessary weight.

-

Corrosion resistance – Naturally resistant to rust and weather conditions, especially when anodised or coated.

-

Workability – Aluminium sheets can be cut, bent, drilled, and welded with ease, making them suitable for custom designs.

-

Eco-friendly – Aluminium is 100% recyclable and retains its properties even after multiple recycling cycles.

-

Cost-effective – Compared to other metals like stainless steel or copper, aluminium sheets are often more affordable while still offering durability.

These benefits explain why aluminium sheets are one of the most in-demand materials worldwide.

Conclusion

Aluminium sheets are a versatile material that continues to shape industries across the globe. Their lightweight strength, durability, and recyclability make them the go-to choice for construction, automotive, aerospace, packaging, and more. With different types and grades available, aluminium sheets can be tailored to meet specific industrial and commercial requirements.

👉 If you are searching for high-quality aluminium sheets in different grades and sizes, Jagdish Metal is here to help. As a trusted supplier and stockist of aluminium sheets in Mumbai, India, Jagdish Metal India provides reliable products that meet global standards. With a strong focus on quality, customer satisfaction, and timely delivery, they are the right partner for your aluminium sheet requirements.