The honeycomb core materials market is experiencing significant momentum across various industries, driven by an increasing emphasis on lightweight, high-strength, and environmentally conscious materials. Designed to emulate the structure of natural honeycombs, these core materials offer an excellent combination of stiffness, strength, and weight reduction, making them indispensable in high-performance applications.

What Are Honeycomb Core Materials?

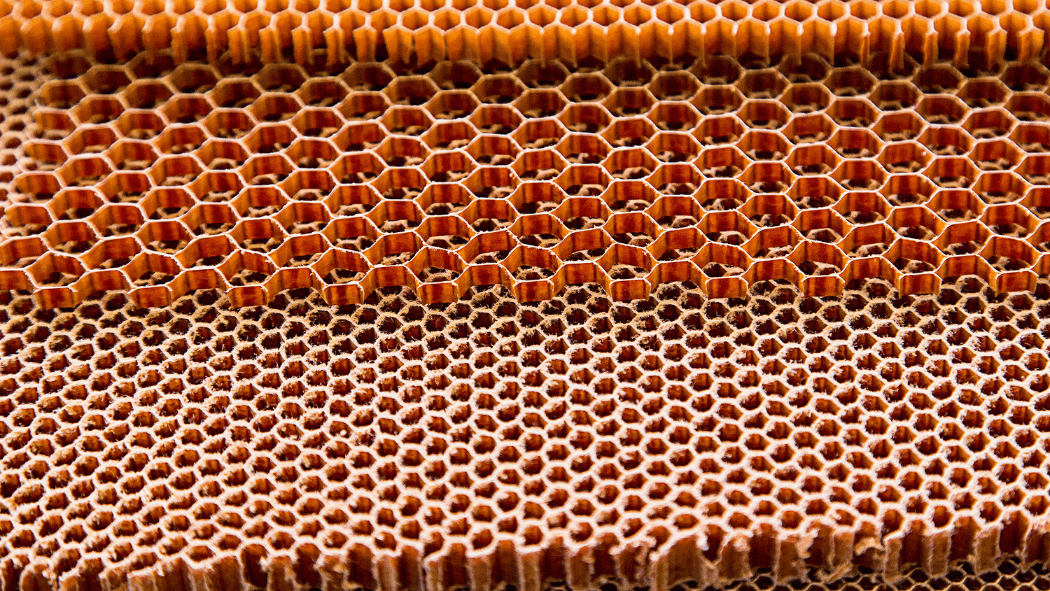

Honeycomb core materials are structured in a hexagonal geometry that maximizes strength while minimizing weight. They are commonly used as core components in sandwich panels, where they are placed between two thin face sheets. This configuration enhances structural performance without significantly adding mass. These materials can be made from various substances such as aluminum, thermoplastics, paper, aramid, and carbon fibers, depending on the end-use requirements.

Key Drivers of Market Growth

Several factors are propelling the widespread adoption of honeycomb core materials:

-

Lightweight Design Trends: The push for fuel efficiency and performance optimization in transportation sectors has accelerated the demand for materials that reduce weight without compromising strength.

-

Growing Aerospace Applications: Honeycomb cores are widely utilized in aircraft flooring, panels, and other structural components due to their strength-to-weight advantages.

-

Sustainability and Recycling: Increasing focus on sustainable materials is leading to innovations in recyclable and biodegradable honeycomb structures, particularly in the packaging and automotive industries.

-

Construction and Infrastructure Expansion: These materials are used in building facades, ceilings, and partition systems where both strength and aesthetics are important.

-

Advancements in Composite Manufacturing: Technological developments in composite fabrication have enabled the efficient integration of honeycomb cores into a wider range of applications.

Technological Innovations Driving the Market

The honeycomb core materials industry is evolving with the integration of cutting-edge technologies:

-

3D Printing and Additive Manufacturing: These technologies are enabling more complex and customized honeycomb structures. Manufacturers can now produce cores with optimized geometries tailored for specific load-bearing or thermal insulation requirements.

-

Nano-Enhanced Honeycomb Structures: Incorporating nanomaterials like carbon nanotubes into honeycomb cores is enhancing their mechanical, electrical, and thermal properties. This advancement is particularly relevant in high-tech sectors such as aerospace and electronics.

-

Bio-Based Composites: Researchers are exploring natural fibers and resins to produce biodegradable honeycomb cores. These innovations align with circular economy principles and are gaining traction in packaging and furniture applications.

-

Smart Materials Integration: Some manufacturers are experimenting with embedding sensors or conductive layers into honeycomb panels, enabling smart monitoring of structural health in real-time.

Major Application Areas

Honeycomb core materials find usage in a variety of sectors:

-

Aerospace & Defense: Critical components such as wing flaps, bulkheads, and panels benefit from reduced weight and increased resilience.

-

Automotive: Used in hoods, roofs, and interiors to enhance fuel efficiency and crashworthiness.

-

Construction: Employed in curtain walls, floors, and prefabricated panels.

-

Packaging: Eco-friendly alternatives to plastics and foams, especially in protective and cushioning materials.

-

Marine: Decks, bulkheads, and interior structures utilize honeycomb cores for buoyancy and lightweight performance.

Material Types and Trends

-

Aluminum Honeycomb: Preferred for aerospace due to its high strength and corrosion resistance.

-

Aramid and Nomex Honeycomb: Known for fire resistance and lightweight features, widely used in aircraft interiors and defense applications.

-

Thermoplastic and Polypropylene Honeycomb: Increasingly used in automotive and packaging owing to cost-effectiveness and recyclability.

-

Paper Honeycomb: Gaining popularity in furniture and packaging due to its eco-friendly profile.

Market Challenges

Despite its benefits, the market faces challenges such as:

-

High Initial Costs: Advanced materials and manufacturing processes can be cost-intensive.

-

Processing Complexities: Integration into specific applications often requires specialized skills and equipment.

-

Raw Material Availability: Fluctuations in raw material supply can impact production and pricing dynamics.

Consumer Trends and Market Behavior

-

Premiumization in Packaging: Brands are moving toward eco-luxury packaging solutions using paper or cardboard honeycomb materials for cushioning and visual appeal.

-

Customization in Architecture: Architects and designers are turning to honeycomb panels not only for function but also for aesthetic facades and interiors that blend strength with visual appeal.

-

Durability in Transportation: Fleet operators and automotive OEMs are valuing the longevity, impact resistance, and fuel-saving advantages of composite panels made with honeycomb cores.

Regional Insights

The demand for honeycomb core materials is growing in both developed and developing economies. Developed regions benefit from mature aerospace and automotive industries, while emerging economies are investing in infrastructure and green packaging solutions, creating fertile ground for market expansion.

Looking ahead, the market is expected to witness continuous innovation, particularly in sustainable and hybrid materials. Collaborations between manufacturers and end-user industries will likely foster the development of cost-effective, high-performance core materials tailored for specific applications. Additionally, automation and digitization in manufacturing are poised to improve production efficiency and scalability.

Honeycomb core materials are at the intersection of performance and sustainability, finding growing acceptance across diverse industries. As the world leans toward lighter, stronger, and more eco-conscious solutions, these materials are set to play a pivotal role in shaping the next generation of products in aerospace, construction, packaging, and beyond.