In the world of modern construction, strength, safety, and speed are more important than ever. As infrastructure demands grow, engineers and builders are turning to smarter, more efficient solutions to connect structural elements. One such innovation that’s transforming construction is the Rebar Coupler—and at SNTP, we are proud to be leading the charge with our high-quality, reliable coupler technology.

What is a Rebar Coupler?

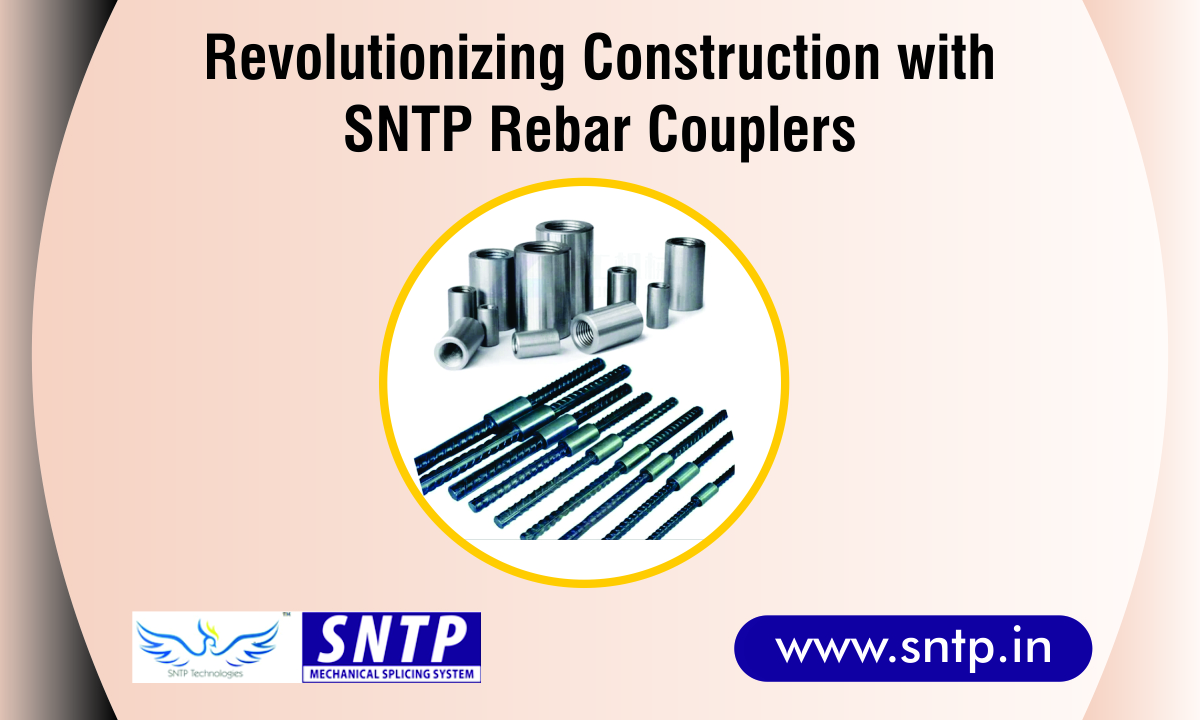

A Rebar couplers is a mechanical connector used to join two pieces of steel reinforcement bars (rebars) end-to-end, ensuring continuity in reinforced concrete structures. Traditionally, overlapping rebars with hooks or lapping methods was common, but it required more steel, took up more space, and often led to congestion in structural elements. Rebar couplers eliminate these issues, offering a neater, stronger, and more space-efficient connection.

Why SNTP Rebar Couplers?

At SNTP, we design and manufacture rebar couplers that meet international standards of performance, safety, and durability. Here’s why our couplers are the preferred choice for engineers and contractors:

1. Superior Strength

Our couplers provide a full-tension splice, meaning the connected rebar performs as if it were a continuous bar. This ensures maximum strength and structural integrity, critical for high-rise buildings, bridges, dams, and other heavy-load structures.

2. Time and Labor Saving

SNTP couplers are easy to install and significantly reduce the time spent on bar placement and binding. This leads to faster project completion and reduced labor costs—benefits that add up on large construction sites.

3. No Need for Lapping

Traditional lapping methods require extra rebar and space, increasing the structural load and material cost. With SNTP rebar couplers, there is no lapping, which not only saves steel but also avoids congestion in beams and columns.

4. Environmentally Friendly

Using couplers means using less steel. Less steel means reduced environmental impact and lower carbon emissions associated with steel production. SNTP is committed to supporting green building practices and sustainable construction.

Applications Across Industries

Rebar couplers from SNTP are ideal for a wide range of construction applications, including:

-

High-rise buildings

-

Bridges and flyovers

-

Nuclear and thermal power plants

-

Metro and railway infrastructure

-

Dams and water treatment facilities

Whether it’s a complex infrastructure project or a commercial high-rise, SNTP couplers provide the dependable reinforcement solution needed for safe and long-lasting structures.

Types of SNTP Rebar Couplers

At SNTP, we offer a variety of coupler types tailored to different construction needs:

-

Standard Couplers – For normal tension/compression applications

-

Position Couplers – For situations where neither rebar can be rotated

-

Transition Couplers – To connect rebars of different diameters

-

Tapered Thread Couplers – Quick assembly with a secure threaded connection

All our couplers are precision-engineered and tested to perform under tough site conditions and demanding project requirements.

Why Choose SNTP?

-

Quality Assurance: Every SNTP product undergoes rigorous quality control and testing

-

Customization: We offer customized solutions to meet specific project needs

-

Technical Support: Our engineering team is always ready to support clients from planning to execution

-

Nationwide Delivery: With our efficient supply chain, we deliver across India and beyond

Conclusion

In today’s fast-paced construction world, SNTP Rebar Couplers are not just an alternative to traditional lapping—they’re the better, smarter choice. Backed by engineering excellence and a commitment to quality, SNTP is helping build the future, one strong connection at a time.

For more information, specifications, or to request a quote, visit [Your Website URL] or contact our sales team.