anti-friction coatings market is emerging as a critical solution for industries seeking to enhance machinery productivity, reduce wear, and optimize operational efficiency. The market has gained prominence across automotive, aerospace, heavy machinery, electronics, and renewable energy sectors. By minimizing friction and extending equipment life, the anti-friction coatings market ensures smoother operation, lower maintenance costs, and improved long-term performance. The growing adoption of advanced coating solutions highlights the anti-friction coatings market’s strategic role in modern industrial practices.

Industrial Equipment Performance Driving Market Demand

The demand for high-performance industrial equipment has become a major driver for the anti-friction coatings market. Bearings, gears, actuators, and precision tools require coatings that prevent friction-related degradation, ensuring reliable operation under high load and continuous use. As industries adopt automated and high-speed machinery, the anti-friction coatings market provides essential solutions for maintaining operational efficiency and reducing downtime. The market’s growth is closely linked to the industrial need for durable, friction-resistant surfaces.

Material Innovations and Technological Advancements

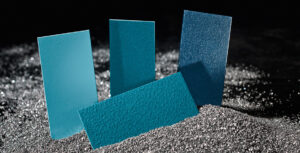

The anti-friction coatings market is experiencing significant innovation in material technologies. Advanced polymer composites, solid lubricants, and nano-engineered coatings offer enhanced wear resistance, low friction, and thermal stability. These developments enable the anti-friction coatings market to support demanding applications, including high-temperature engines, precision manufacturing tools, and heavy industrial machinery. By continuously improving coating performance, the anti-friction coatings market strengthens component durability and industrial reliability.

Automotive Sector Influence on Market Growth

The automotive industry remains a primary driver of the anti-friction coatings market. Engine components, transmission systems, bearings, and EV powertrain elements benefit from coatings that reduce friction, enhance efficiency, and prolong service life. The rise of electric and hybrid vehicles has created additional demand for specialized coatings that improve battery performance, reduce mechanical noise, and enable lightweight construction. This trend underscores the anti-friction coatings market’s pivotal role in advancing automotive performance and sustainability objectives.

Aerospace and Defense Sector Applications

In aerospace and defense, the anti-friction coatings market provides solutions for components exposed to extreme mechanical stress, temperature variations, and high-pressure environments. Turbine blades, landing gear, actuators, and structural components require coatings that ensure durability, low friction, and long-lasting performance. As global aerospace fleets expand and defense programs scale, the anti-friction coatings market supports operational reliability, reduces maintenance intervals, and enhances the lifespan of critical equipment.

Automation and Precision Manufacturing Integration

The integration of automation and precision manufacturing has boosted the relevance of the anti-friction coatings market. High-speed machinery, robotic systems, and assembly lines depend on coatings to reduce friction, prevent wear, and maintain consistent output. By providing smooth motion, improved reliability, and reduced vibration, the anti-friction coatings market ensures that automated and precision manufacturing operations function efficiently. This integration emphasizes the market’s importance in supporting advanced industrial processes.

Sustainability and Eco-Friendly Innovations

Sustainability trends are influencing the anti-friction coatings market, with increasing emphasis on environmentally friendly solutions. Water-based, low-VOC, and non-toxic coatings reduce environmental impact while maintaining high performance. By lowering lubricant consumption and maintenance frequency, the anti-friction coatings market supports greener industrial practices and energy efficiency. Organizations focused on sustainable operations are increasingly adopting anti-friction coatings to meet environmental regulations and optimize resource use.

Renewable Energy and Heavy Industry Opportunities

The anti-friction coatings market is expanding in renewable energy and heavy industrial applications. Wind turbines, hydropower systems, and solar tracking mechanisms rely on coatings that maintain smooth operation under continuous load and harsh environmental conditions. Similarly, heavy machinery in steel production, mining, and construction benefits from coatings that enhance durability, reduce wear, and extend operational life. The anti-friction coatings market plays a critical role in supporting continuous operation and long-term reliability in these sectors.

Nanotechnology and Smart Coating Solutions

Innovations in nanotechnology and smart coatings are reshaping the anti-friction coatings market. Nano-structured coatings provide superior surface hardness, reduced friction, and enhanced wear resistance. Smart coatings enable predictive maintenance, real-time monitoring, and adaptive lubrication, aligning with Industry 4.0 initiatives. These advancements enhance the anti-friction coatings market’s contribution to operational efficiency, reduced downtime, and improved machinery reliability across industrial sectors.

Regional Market Insights

Asia-Pacific dominates the anti-friction coatings market due to rapid industrialization, extensive automotive production, and growing electronics manufacturing. North America and Europe excel in technological innovation, R&D investment, and adoption of sustainable coatings. Emerging regions such as Latin America, the Middle East, and Africa are increasingly adopting anti-friction coatings to support industrial growth and infrastructure development. These regional factors highlight the global relevance and growth potential of the anti-friction coatings market.

Challenges and Strategic Outlook

The anti-friction coatings market faces challenges related to cost optimization, substrate compatibility, and performance standardization. Addressing these issues requires ongoing research, process innovation, and advanced material development. Future growth will be driven by smart coatings, nano-technology integration, and digital performance monitoring, reinforcing the anti-friction coatings market’s strategic importance in modern industrial applications.

Conclusion

The anti-friction coatings market is expanding as industries prioritize operational efficiency, durability, and sustainability. Innovations in materials, automation integration, smart coatings, and eco-friendly solutions are driving market growth. The anti-friction coatings market remains essential for improving machinery performance, reducing wear, and ensuring long-term operational reliability across diverse industrial sectors.

Description: Discover the anti-friction coatings market’s innovations in sustainable, high-performance, and smart coatings. Explore how the market enhances machinery efficiency, reduces wear, and ensures operational reliability in automotive, aerospace, heavy industry, and renewable energy sectors.