Construction projects, especially large-scale ones, can have significant environmental impacts if not managed properly. One of the most important challenges during construction is preventing pollutants from entering nearby waterways. Among the various erosion control techniques, silt fences have emerged as an effective and affordable solution. These barriers play a crucial role in protecting the environment by reducing sediment runoff, which is a common cause of water pollution during construction activities. This article explores how silt fences function, their benefits, and the role of Silt fence manufacturers and exporters in ensuring that these barriers are effectively used in construction projects.

Understanding the Role of Silt Fences in Erosion Control

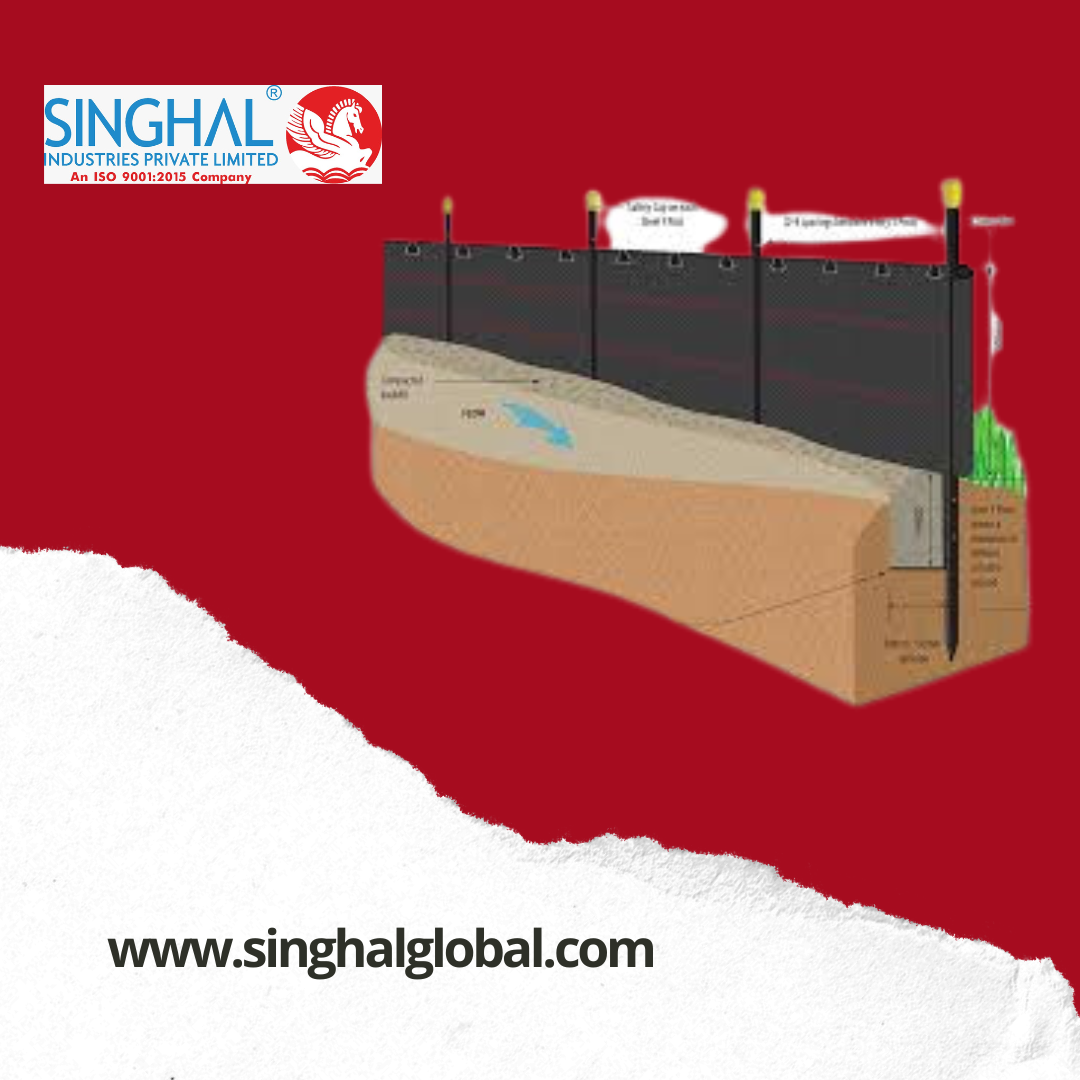

Silt fences are temporary barriers made of permeable fabric that are installed on construction sites to control soil erosion and prevent sediment-laden runoff from entering nearby water bodies. The primary function of a silt fence is to filter out sediment from stormwater runoff, allowing water to pass through while trapping soil particles. Typically, silt fences are installed along the perimeter of construction sites, near areas where soil disturbance is most likely to occur, such as excavation zones or stockpiles of materials.

These fences are particularly effective in areas where the construction activities might lead to the erosion of exposed soil. Without these protective barriers, rainwater can easily wash away large amounts of soil, carrying pollutants such as sediments, nutrients, and chemicals into rivers, lakes, and other water bodies. By trapping sediments, silt fences help to prevent water pollution and maintain water quality in surrounding environments.

How Silt Fences Prevent Pollutants from Entering Waterways

The mechanism behind silt fences involves their ability to intercept stormwater runoff before it can carry sediment into waterways. The fabric used for the fences is specially designed to allow water to flow through while capturing particles of soil. The structure of a silt fence allows water to pass through gradually, which helps to reduce the speed of water flow and encourages the deposition of suspended sediments. The fence acts as a filter, catching larger particles while letting cleaner water seep through. This process prevents pollutants like clay, silt, and other debris from entering rivers, streams, or lakes.

During rainfall, when water would otherwise flow freely and take pollutants with it, silt fences serve as a barrier, directing the flow of water in a controlled manner. This filtration system helps maintain the natural balance of aquatic ecosystems by preventing nutrient overloads and reducing the potential for algal blooms and other water quality issues that can be caused by sediment pollution.

The Environmental Benefits of Using Silt Fences in Construction

Silt fences provide significant environmental benefits by reducing the amount of sediment that enters the surrounding environment. When sediments are allowed to wash into waterways, they can cause a variety of problems. For example, excess sediment in water can smother aquatic plants, disrupt fish habitats, and reduce oxygen levels, making it harder for marine life to survive. Furthermore, sediment-laden water can lead to the degradation of water quality, which is harmful not only to aquatic ecosystems but also to the communities that rely on these water sources for drinking, recreation, and irrigation.

By installing silt fences on construction sites, developers can mitigate these risks and ensure that construction activities do not negatively impact nearby waterways. Silt fences are especially important in areas near wetlands, rivers, or lakes, where the potential for sediment runoff is high. By preventing soil erosion and sedimentation, silt fences contribute to maintaining the health of these sensitive ecosystems.

The Importance of Quality Silt Fences in Construction Projects

While silt fences can be incredibly effective, their performance largely depends on the quality of the materials used and the proper installation techniques. This is where silt fence manufacturers play a crucial role. High-quality silt fences made from durable, UV-resistant fabric ensure that the barriers last throughout the duration of a construction project, even under harsh weather conditions. Low-quality fences, on the other hand, may break down quickly or fail to perform effectively, leading to inadequate sediment control and potential pollution.

Silt fence manufacturers are responsible for ensuring that their products meet industry standards and regulations. In countries like India, where construction activity is booming, reliable silt fence manufacturers are vital in supplying the market with effective erosion control solutions. These manufacturers often offer a range of products tailored to different project needs, from small residential developments to large-scale infrastructure projects. They also ensure that the materials used in their fences are both effective at sediment control and environmentally safe.

The Role of Silt Fence Exporters in Global Construction

In addition to local manufacturers, Silt fence exporters also play an essential role in ensuring that these erosion control solutions are available worldwide. Many construction projects across the globe, especially in regions with rapid urban development, require reliable erosion control methods. Silt fence exporters bridge the gap between manufacturers and international markets by distributing high-quality products to construction sites outside their domestic regions.

Silt fence exporters help to ensure that construction projects worldwide adhere to environmental regulations by providing them with effective sediment control solutions. By exporting durable, high-quality silt fences, these exporters contribute to improving water quality and reducing pollution in waterways across various countries. As environmental concerns continue to rise, the demand for reliable silt fence exporters is expected to grow, making it easier for construction companies worldwide to access the products they need to protect the environment.

Key Considerations When Choosing a Silt Fence Supplier

Choosing the right silt fence supplier is crucial for ensuring that construction projects are compliant with environmental regulations. Whether you are looking for a local silt fence manufacturer in India or an international exporter, there are several key factors to consider:

- Material Quality: Ensure that the silt fence is made from durable, UV-resistant fabric that can withstand various weather conditions without deteriorating.

- Installation Instructions: Proper installation is critical to the effectiveness of a silt fence. Suppliers should provide clear installation guidelines to ensure optimal performance.

- Certifications and Standards: It is important to select a supplier that adheres to industry standards and regulations regarding erosion control and environmental protection.

- Customization Options: Depending on the specific needs of a construction site, custom-sized silt fences may be required. A reliable supplier should be able to accommodate special requests.

- Delivery and Support: Suppliers should offer timely delivery and provide customer support to assist with any issues that arise during installation or use.

Silt Fence Manufacturers and Exporters in India: Meeting Growing Demand

India, with its rapidly growing construction industry, is home to numerous silt fence manufacturers that cater to the increasing demand for erosion control products. As urbanization and infrastructure development expand, the need for effective sediment control solutions has never been greater. Indian manufacturers are now supplying not only local markets but also exporting silt fences to countries around the world. Silt fence manufacturers in India play a critical role in ensuring that both small and large-scale construction projects are environmentally sustainable. They produce fences that meet the specific needs of various construction sites, from roads to high-rise buildings. In addition to quality products, these manufacturers also prioritize customer service, helping construction companies navigate the installation process and ensuring the effectiveness of their silt fences.

Conclusion: Protecting Waterways for Future Generations

Silt fences are an essential tool for preventing pollutants from entering waterways during construction projects. By filtering out sediment and allowing water to flow through while capturing harmful particles, silt fences play a critical role in protecting the environment and maintaining water quality. Silt fence manufacturers, both in India and globally, help to ensure that high-quality barriers are available to construction sites, contributing to the overall health of aquatic ecosystems.

The global construction industry is increasingly recognizing the importance of sustainable building practices, and the use of silt fences is a key part of that commitment. By working with reliable silt fence manufacturers and exporters, construction companies can ensure that their projects comply with environmental standards while also contributing to the preservation of vital water resources for future generations.

Frequently Asked Questions (FAQs)

1. Can silt fences be used for long-term projects?

While silt fences are primarily designed for short-term erosion control, they can be used for longer projects if maintained properly. In some cases, additional erosion control measures may be needed, especially if the project lasts for a year or more, or if weather conditions put additional strain on the silt fence.

2. How often should silt fences be inspected?

Silt fences should be inspected regularly, especially after heavy rainfall or storms. Inspections should include checking for fabric damage, sediment build-up, and proper installation. If any issues are found, the fence should be repaired or replaced immediately to maintain its effectiveness.

3. What are some common problems with silt fences?

Some common issues with silt fences include:

- Fabric tearing or pulling away from the posts.

- Sediment accumulation exceeding the capacity of the fence.

- Water flowing underneath the fence.

- Improper installation or failure to secure the fabric correctly.